In the modern textile industry, Cordura fabric is known for its excellent durability and versatility. Originally developed by DuPont, this high-performance fabric has become an important material in outdoor equipment, military clothing and industrial applications. Whether it is adventure in extreme environments or the practical needs of daily life, Cordura fabric can provide reliable performance and comfort.

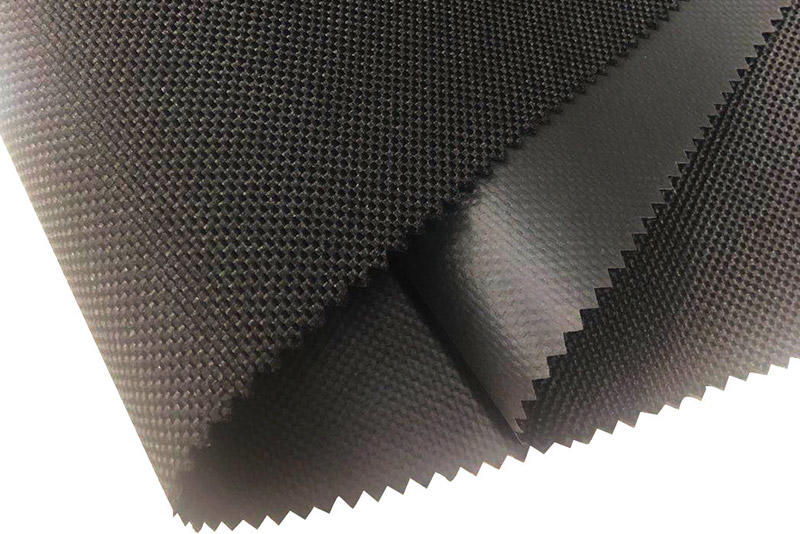

Cordura fabric is a high-strength nylon fabric, mainly made of polyamide fibers such as nylon 6,6. It has extremely high abrasion resistance, tear resistance and waterproof properties through special weaving and coating processes. The name of Cordura fabric comes from its brand-Cordura, which is a brand focusing on high-performance textiles and is widely used in various scenarios that require high durability.

Features of Cordura fabric

Excellent wear resistance

The most notable feature of Cordura fabric is its excellent wear resistance. Compared with ordinary nylon, Cordura fabric is several times more wear-resistant, which makes it an ideal choice for making backpacks, mountaineering equipment and military clothing.

Lightweight Design

Despite its extreme strength, Cordura fabric is very light. This lightweight property makes it popular in outdoor sports and military fields because it can reduce the burden on users while maintaining durability.

Tear Resistance

Cordura fabric uses a tightly woven fiber structure that can effectively resist tears and punctures. It can maintain its integrity even when used in harsh environments.

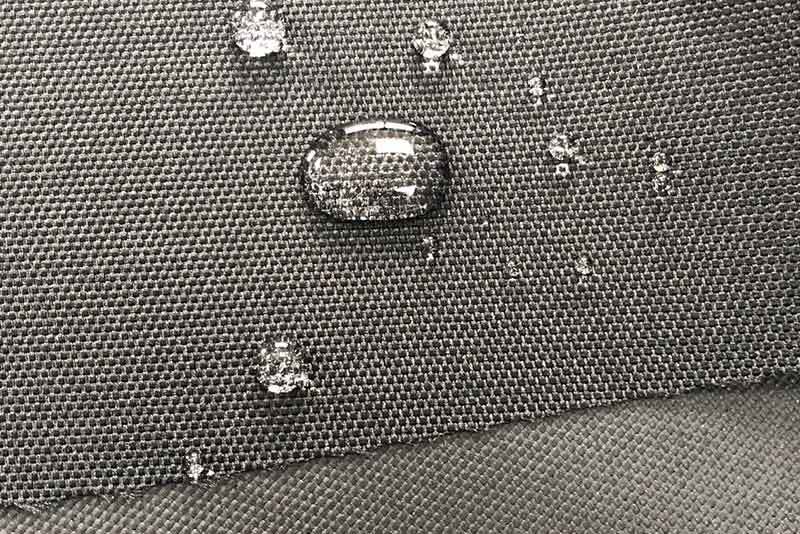

Waterproof and Breathable

Many Cordura fabrics are specially coated or laminated to make them waterproof while still maintaining a certain degree of breathability. This property makes them ideal for making outdoor clothing and equipment.

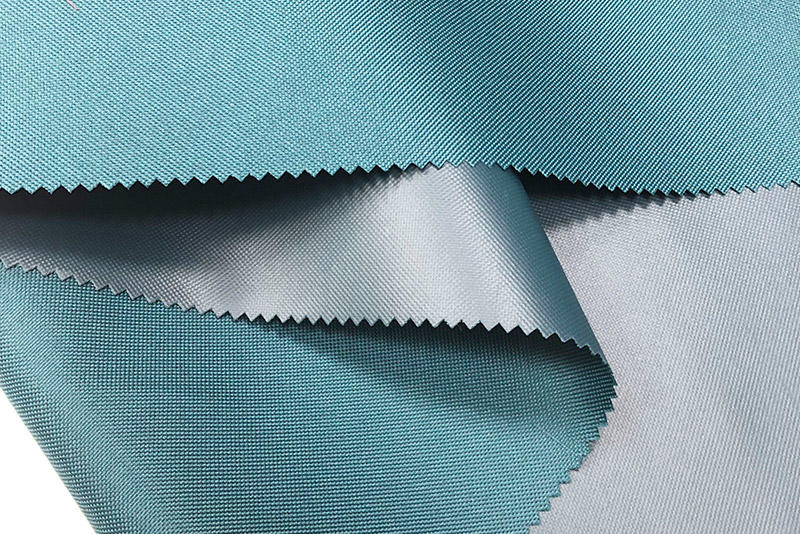

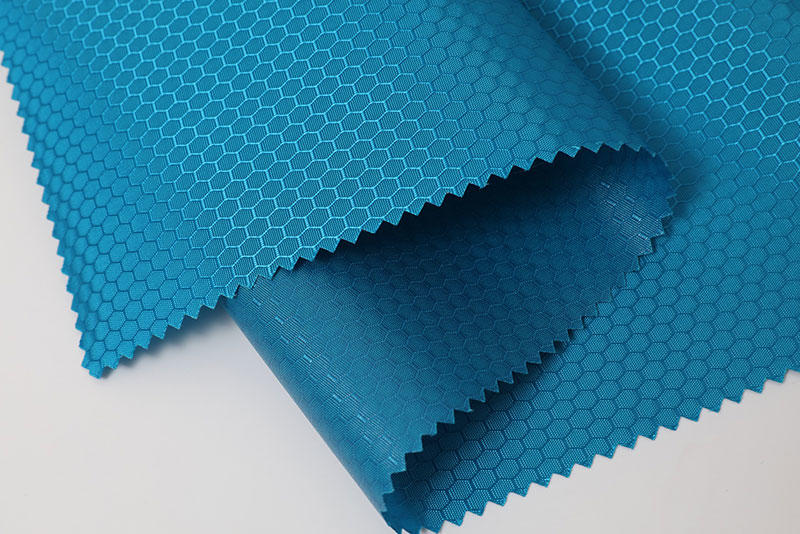

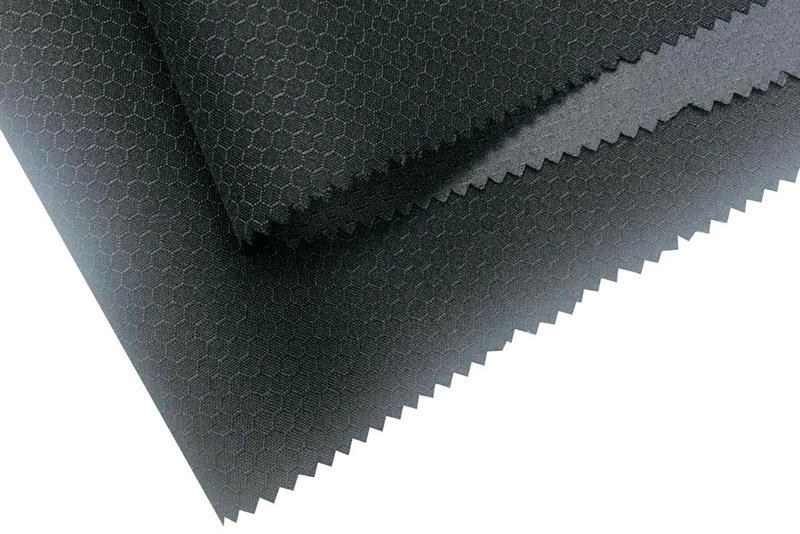

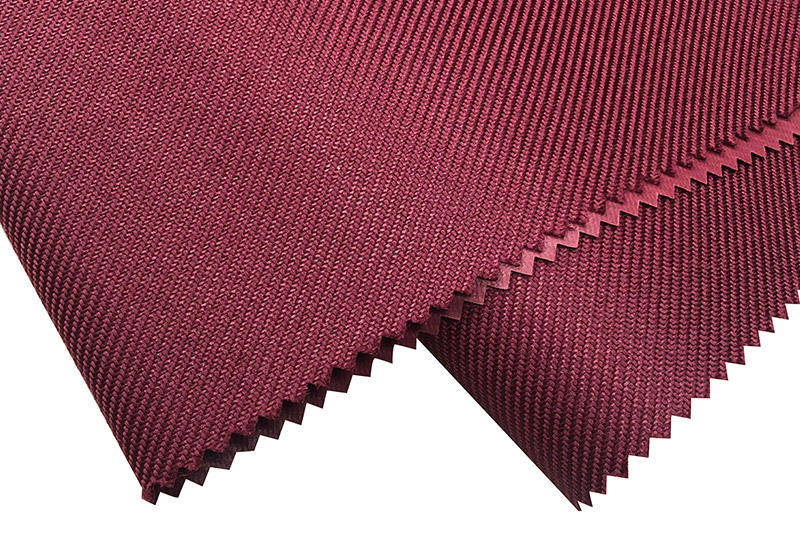

Variety and Customizability

Cordura fabrics are available in a variety of thicknesses, textures and colors, and can be customized for different application scenarios. Whether it is a soft knit fabric or a sturdy canvas material, it can meet specific needs.

Cordura Fabric Manufacturing Process

The production process of Cordura fabric involves several key steps:

Raw Material Selection

The main component of Cordura fabric is nylon 6,6 fiber, which has excellent strength and heat resistance. In addition, other functional fibers such as elastic fibers or flame retardant fibers can be added as needed.

Textile Technology

Using advanced textile technology, nylon fibers are woven into a tight and uniform fabric structure. Different weaving methods affect the appearance, feel and performance of the fabric.

Coating and treatment

In order to enhance waterproof, stain-proof or fire-resistant properties, Cordura fabrics are usually coated or other chemically treated. These treatments not only improve the functionality of the fabric, but also extend its service life.

Quality Inspection

Each batch of Cordura fabrics needs to undergo rigorous quality inspection to ensure that it meets the wear resistance, tear resistance and other performance indicators.

Application areas of Cordura fabrics

Outdoor equipment

Cordura fabrics are widely used in products such as mountaineering bags, tents, sleeping bags and outdoor clothing. Its wear resistance and waterproof properties make it the material of choice for outdoor enthusiasts.

Military and tactical equipment

The military field has extremely high requirements for the durability of equipment, so Cordura fabrics are used to make military backpacks, tactical vests and protective clothing. Its tear resistance and lightweight design are particularly suitable for battlefield environments.

Fashion and casual wear

In recent years, Cordura fabrics have gradually entered the fashion field and are used to make products such as jackets, jeans and shoes. Its unique texture and durability provide designers with more creative space.

Industrial Uses

In the industrial field, Cordura fabrics are used to make work clothes, protective gloves and heavy-duty transport bags. Its high strength and durability can cope with various harsh working environments.

Luggage and Bags

Cordura fabrics are also commonly used in products such as suitcases, handbags and wallets because they need to withstand frequent use and wear.

Market Trends and Development Prospects

As consumers pursue high-quality and functional products, the Cordura fabric market is ushering in new growth opportunities. Here are a few trends worth paying attention to:

Sustainable Development

DuPont and other manufacturers are launching environmentally friendly Cordura fabrics, such as products made of recycled nylon. This not only reduces resource waste, but also caters to consumers' demand for sustainable development.

Technological Innovation

New coating technologies and fiber modification technologies are constantly improving the performance of Cordura fabrics. For example, adding antibacterial functions or improving breathability to meet more diverse needs.

Cross-border Cooperation

Cordura fabric brands have cooperated with well-known brands in other fields to launch many innovative products. For example, working with sports brands to develop high-performance sportswear, or working with luxury brands to create high-end fashion items.

Global Expansion

As the global market expands, Cordura fabrics are entering more emerging markets, especially in Asia and Africa, where demand continues to grow.

With its excellent wear resistance, lightweight design and versatility, Cordura fabrics have become an important part of the modern textile industry. Whether in outdoor adventures, military missions or daily life, Cordura fabrics have demonstrated irreplaceable value. In the future, with the advancement of technology and changes in market demand, this high-performance fabric will surely shine in more fields and bring more convenience and possibilities to human life. From practicality to fashion, Cordura fabrics are redefining the boundaries of textiles and becoming synonymous with durability and innovation.

English

English 简体中文

简体中文 русский

русский Español

Español