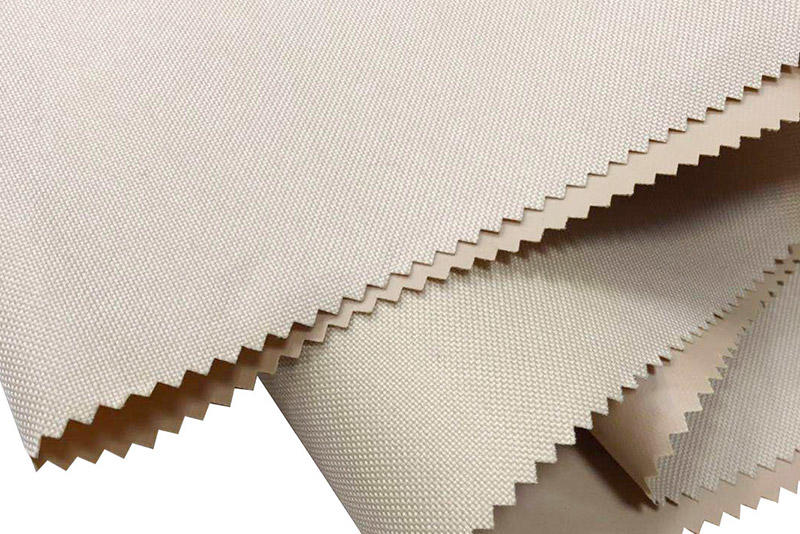

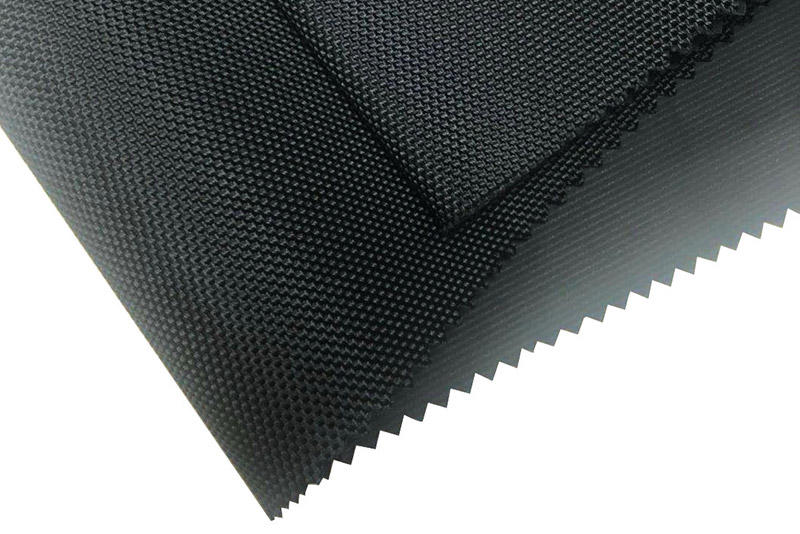

During the production process of Jacquard Oxford Fabric, there are several key requirements for pattern accuracy and fabric thickness that must be strictly adhered to in order to maintain high-quality standards. These requirements are critical to ensuring that the fabric meets both aesthetic and functional specifications for various end uses, such as in clothing, bags, upholstery, and outdoor gear.

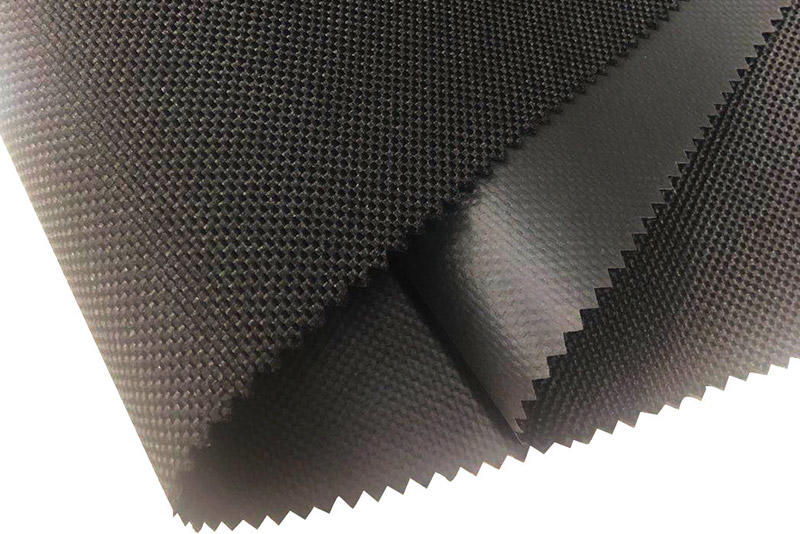

Pattern accuracy is crucial in Jacquard Oxford fabric because the fabric features intricate woven patterns created through the Jacquard weaving technique. The accuracy of these patterns directly impacts the fabric's aesthetic appeal and functionality. Key requirements include:

The Jacquard weaving process must precisely reproduce the design intended by the manufacturer. Any distortion or misalignment of the pattern can affect the fabric's overall look and usability.

Patterns must align consistently across the fabric. The repeat length, or how the design repeats across the fabric, must remain uniform throughout the entire production run.

The warp (vertical threads) and weft (horizontal threads) must be woven with perfect tension control to avoid any misalignment, which could cause the pattern to distort or appear skewed.

Advanced Jacquard looms are often equipped with sensors that monitor the alignment of the threads in real time to prevent pattern errors. If misalignment is detected, the loom automatically adjusts or signals the operator.

No Distortion in Fine Details: (such as fine motifs or logos) must be woven without any blurring or distortion. The finer the detail, the more precise the machine settings must be.

The pattern should be sharp with clear edges, especially if it involves geometric shapes, logos, or text. A lack of clarity may lead to a loss in visual quality and brand reputation.

Since Jacquard Oxford fabrics often incorporate multi-color patterns, maintaining consistent dye application is crucial. This ensures that each section of the design is colored accurately and uniformly.

The colors in the pattern must align properly in both the horizontal (weft) and vertical (warp) directions to create a uniform design across the entire fabric.

The Jacquard loom should be calibrated correctly to handle the pattern complexity. The tension on the yarns and the mechanism that controls the warp and weft must be adjusted to ensure precise pattern weaving.

Modern Jacquard looms have built-in error checking and correction systems to prevent misweaving. This includes optical and digital sensors that check for any irregularities in pattern execution.

Fabric thickness is an important attribute that influences the fabric's durability, comfort, and suitability for specific applications. The thickness of Jacquard Oxford fabric needs to be consistent throughout the production process. Below are key requirements:

The fabric should maintain a consistent thickness throughout its entire width and length. Variations in thickness can affect both the appearance and strength of the fabric, especially in areas where the fabric will be cut and sewn.

There is generally a permissible tolerance range (e.g., ±0.1 mm) for thickness variation across different fabric batches, but excessive variation could lead to defects. This is especially important for high-end products or those that require precise cutting, such as upholstery or technical apparel.

Pattern accuracy requires precise loom calibration, pattern alignment, and consistency in design reproduction.

Fabric thickness must remain uniform, with careful control over yarn density, weave structure, and finishing processes to balance durability with softness.

By adhering to these requirements, manufacturers can produce Jacquard Oxford fabrics that are aesthetically pleasing, durable, and suitable for a wide range of applications.

English

English 简体中文

简体中文 русский

русский Español

Español