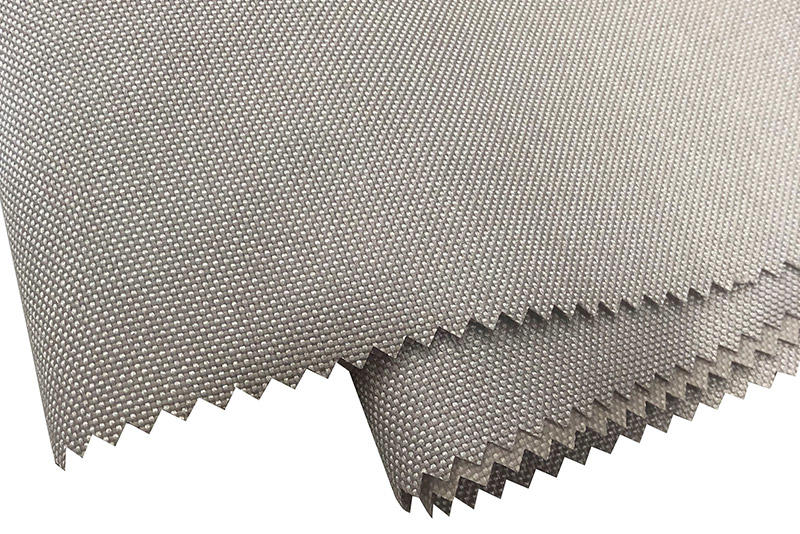

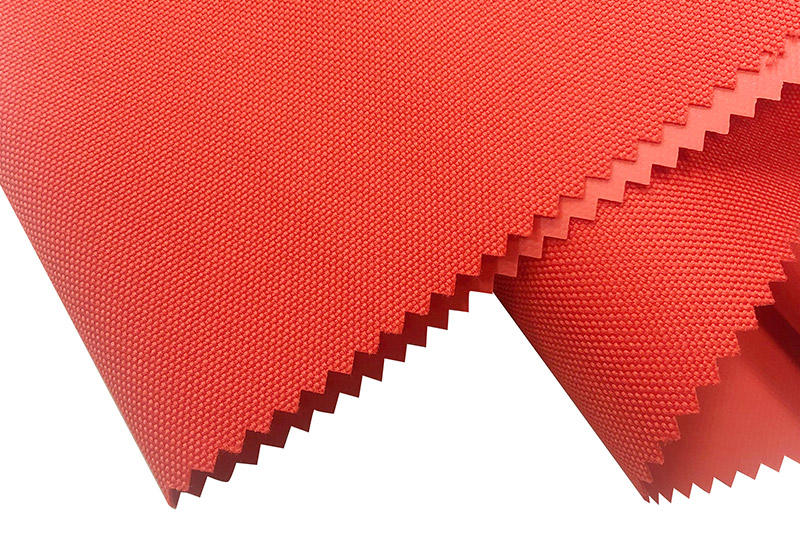

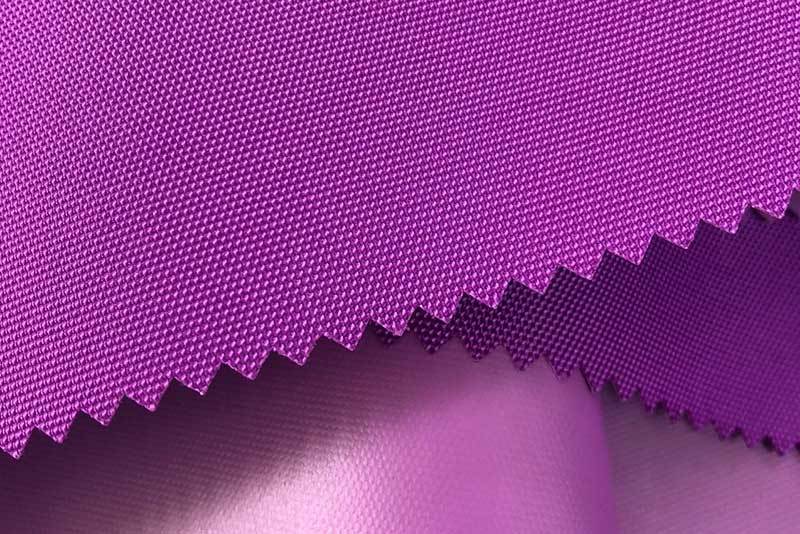

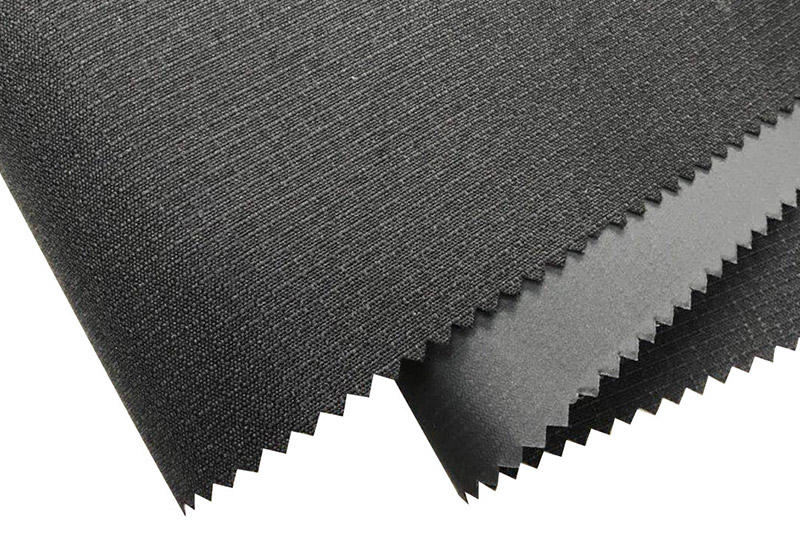

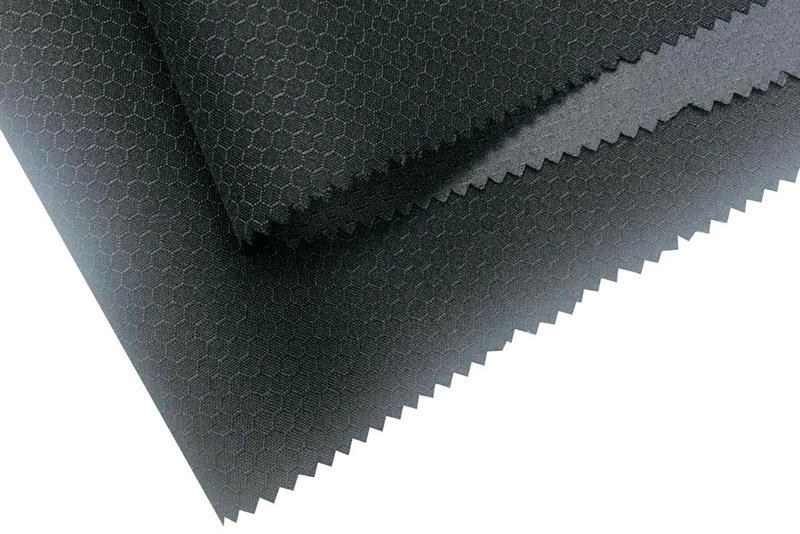

Ripstop fabric is a type of woven fabric that incorporates reinforcement threads at regular intervals to create a grid pattern. These stronger threads help prevent the fabric from tearing, as any rips or holes will be contained by the grid. The most common materials used for ripstop fabrics are nylon and polyester, but it is also available in natural fibers such as cotton. The grid pattern of ripstop fabric typically appears as small squares or diamonds, which are woven into the fabric at fixed intervals.

The structure of ripstop fabric is what gives it its tear-resistant qualities. If the fabric does tear, the grid pattern will stop the tear from spreading, which can be a lifesaver in certain environments where failure of the material could have serious consequences. This unique feature has made ripstop fabric a highly sought-after material for industries that demand high-performance textiles.

Properties of Ripstop Fabric

Ripstop fabric stands out due to several key properties:

Strength and Durability

Ripstop fabric is incredibly strong. The reinforcement threads woven into the fabric help it resist tearing, making it much more durable than regular fabric. This strength makes it perfect for use in high-stress environments.

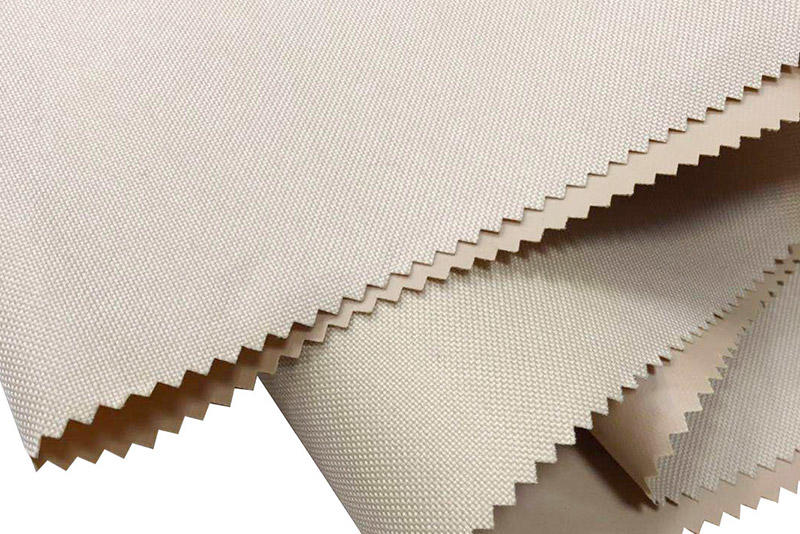

Lightweight

Despite its strength, ripstop fabric is lightweight and flexible. This characteristic makes it suitable for a variety of applications where bulk or weight would be a concern, such as in outdoor gear, military clothing, and sports equipment.

Breathability and Comfort

Ripstop fabrics made from natural fibers, such as cotton, can offer excellent breathability, which is important in clothing and outdoor gear. This makes the fabric comfortable for extended use in warm weather or physically demanding situations.

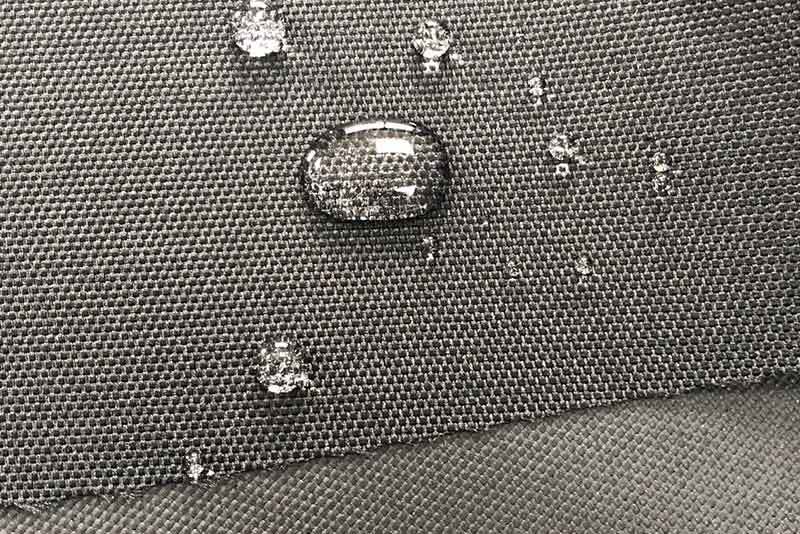

Water Resistance

Many types of ripstop fabric come with additional coatings or treatments, such as polyurethane, to make them water-resistant. This property is essential in outdoor gear like tents, jackets, and backpacks, as it helps protect against the elements.

Applications of Ripstop Fabric

Ripstop fabric’s unique qualities make it ideal for use in a variety of applications. Here are some of the most common:

Outdoor and Adventure Gear

Ripstop fabric is a staple in the outdoor and adventure gear industry. Tents, sleeping bags, hiking backpacks, and jackets are commonly made from ripstop materials because of their tear resistance, water resistance, and lightweight properties. The fabric helps gear withstand the rigors of outdoor use, ensuring that it lasts longer and performs better under harsh conditions.

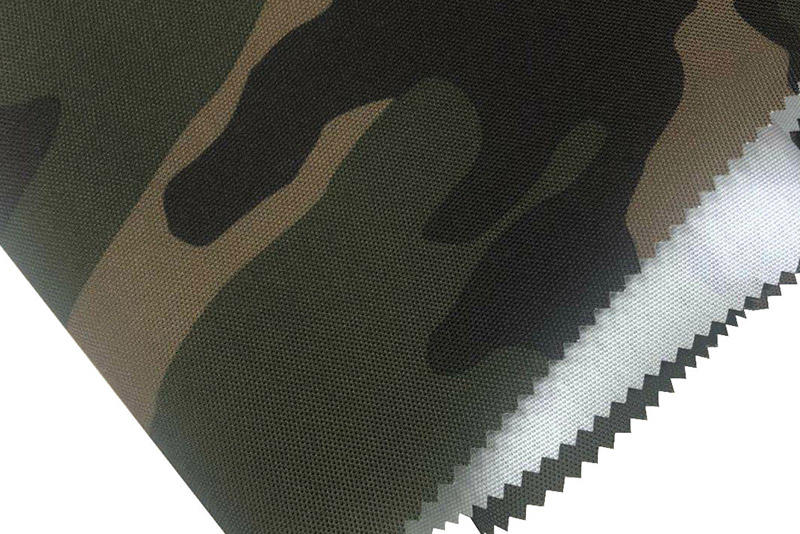

Military and Tactical Gear

One of the original uses of ripstop fabric was in military uniforms and parachutes. The fabric is ideal for tactical gear because it can stand up to the demands of combat and rough conditions. Military-grade ripstop fabric is designed to resist tears, abrasions, and exposure to harsh weather, providing reliable protection for soldiers and tactical personnel.

Sports Equipment

Ripstop fabric is also used in a wide range of sporting equipment, such as kites, sails, and parachutes. Its tear-resistant properties help prevent catastrophic failures during high-stress situations, while its lightweight nature ensures that it doesn’t add unnecessary weight.

Protective Clothing and Workwear

Ripstop fabric is used in protective workwear, such as coveralls, aprons, and gloves, where durability is essential. Workers in industries like construction, manufacturing, and emergency response benefit from ripstop fabric’s ability to withstand wear and tear, offering a longer lifespan than regular fabrics.

Bags and Luggage

High-quality backpacks, travel bags, and luggage often incorporate ripstop fabric due to its tear resistance and lightweight nature. The fabric ensures that bags can withstand the rough handling they experience during travel while keeping the contents safe from the elements.

English

English 简体中文

简体中文 русский

русский Español

Español