The interaction between cationic fabric and anti-odor treatments can differ significantly between synthetic and natural fibers due to the distinct characteristics of each type of fiber. Here’s how these interactions typically differ:

Fiber Structure and Composition

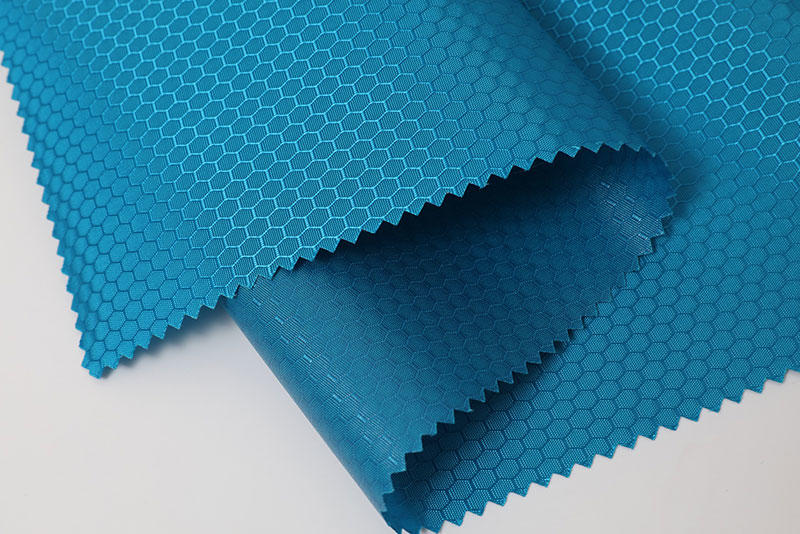

Synthetic Fibers (e.g., polyester, nylon): Synthetic fibers like polyester and nylon have a smoother, more uniform surface structure, which allows for easier application of finishes, including cationic treatments and anti-odor agents. Since synthetic fibers are more hydrophobic (water-repelling), they do not absorb moisture as readily, which can sometimes limit the effectiveness of anti-odor treatments that rely on moisture absorption to combat bacteria and odor.

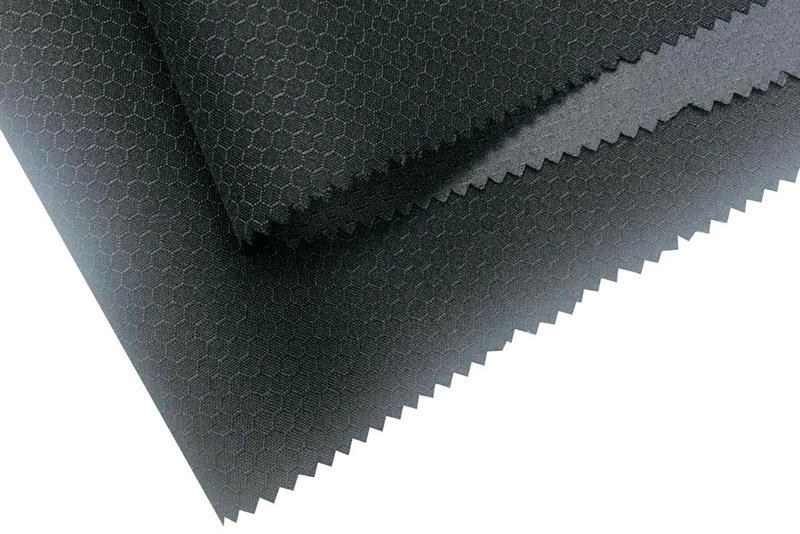

Natural Fibers (e.g., cotton, wool): Natural fibers have a more porous and absorbent structure, which can more readily take up both moisture and treatments. This makes them more susceptible to retaining moisture and providing a favorable environment for bacteria to grow. However, the porous nature can also make it easier for anti-odor treatments to bond with the fibers, as long as they are compatible with the fiber’s hydrophilic (water-attracting) characteristics.

Effect of Cationic Treatment

Synthetic Fibers: Cationic treatments work well with synthetic fibers because they are typically made of polymers that can easily interact with the positively charged chemicals used in the cationization process. The cationic charge can help the fiber better retain and bond with anti-odor treatments, improving the longevity and effectiveness of odor control. However, since synthetic fibers are hydrophobic, the anti-odor treatments may not be as effective in terms of moisture absorption, and might rely more on chemical agents that inhibit bacterial growth on the surface.

Natural Fibers: Natural fibers, being more hydrophilic, may interact differently with cationic treatments. The cationization process still helps in retaining anti-odor agents, but because the fibers are more absorbent, the anti-odor treatments often need to be more specifically designed to work in conjunction with the fiber's moisture-absorbing properties. In natural fibers, the anti-odor treatments may be more effective because the fabric can hold onto moisture and, by extension, more of the antimicrobial or odor-neutralizing agents.

Performance of Anti-Odor Treatments

Synthetic Fibers: In synthetic cationic fabrics, anti-odor treatments are often based on chemical agents such as silver nanoparticles, copper ions, or other antimicrobial compounds. These treatments can bind effectively to the fibers through the cationic charge, creating a more durable and long-lasting protection against odor-causing bacteria. However, the effectiveness of these treatments can diminish if the fabric doesn’t absorb moisture well, as moisture is often a key factor in the growth of odor-causing bacteria.

Natural Fibers: For natural fibers, anti-odor treatments may rely more heavily on natural agents like activated charcoal, essential oils, or plant-based compounds. These agents are often better absorbed into the fibers, and because natural fibers tend to retain moisture, they can create a more favorable environment for these treatments to work. However, natural fibers may require more frequent reapplication of anti-odor treatments, as their porous structure can cause the treatment to wash out more easily over time.

Moisture Management

Synthetic Fibers: Synthetic fibers are often designed for better moisture-wicking properties, but they do not inherently hold moisture. This characteristic can sometimes work against anti-odor treatments, as bacteria that cause odor thrive in moist environments. Anti-odor treatments on synthetic fabrics may focus more on reducing bacterial growth on the surface or using chemicals that trap odor molecules.

Natural Fibers: Natural fibers, on the other hand, are more moisture-retentive, which can encourage bacteria growth and contribute to odors if not treated. However, the moisture retention of natural fibers can work synergistically with anti-odor treatments, as moisture can help activate the antimicrobial properties, particularly if the treatments are designed to target bacteria in moist environments.

Durability of Anti-Odor Treatments

Synthetic Fibers: The durability of anti-odor treatments on synthetic cationic fabrics is generally higher, as the smooth surface of synthetic fibers allows for more durable bonding of chemical treatments. These treatments are less likely to wash out quickly and may remain effective through many washes.

Natural Fibers: While anti-odor treatments may be effective initially on natural fibers, they tend to degrade faster due to the more porous and absorbent nature of the fibers. The treatments may wash out more quickly, requiring reapplication more frequently, especially after multiple washes.

Environmental Considerations

Synthetic Fibers: Synthetic fibers are often derived from petrochemical sources and may require more chemical treatments, including cationic processes and anti-odor finishes. These treatments may involve synthetic chemicals that can be less environmentally friendly.

Natural Fibers: Natural fibers are typically more biodegradable and may be more compatible with natural, plant-based anti-odor treatments. However, the treatments applied to natural fibers may not always be as long-lasting or as effective as those used on synthetic fabrics, depending on the specific needs of the application.

English

English 简体中文

简体中文 русский

русский Español

Español