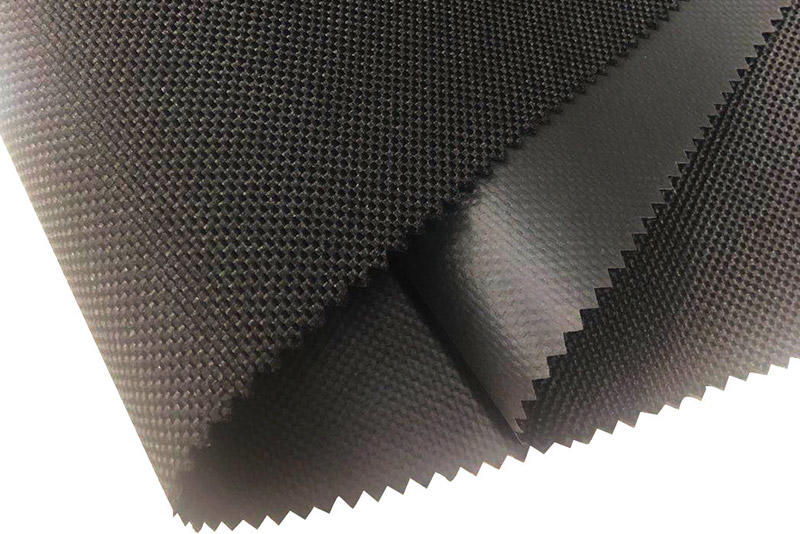

Nylon fabric is a kind of synthetic fiber, which has the characteristics of good toughness, abrasion resistance, scratch resistance, tensile and compressive resistance, strong corrosion resistance, light weight, easy dyeing, and easy cleaning. If backpack products require light and strong fabrics Durable, generally choose nylon fabrics. In addition, the hygroscopicity of nylon fabrics is a better variety among synthetic fiber fabrics, so bags made of nylon will be more comfortable and breathable to carry, and nylon fabrics are lightweight fabrics, and the weight of the bags produced will also be higher than other fabrics. Comes out lighter.

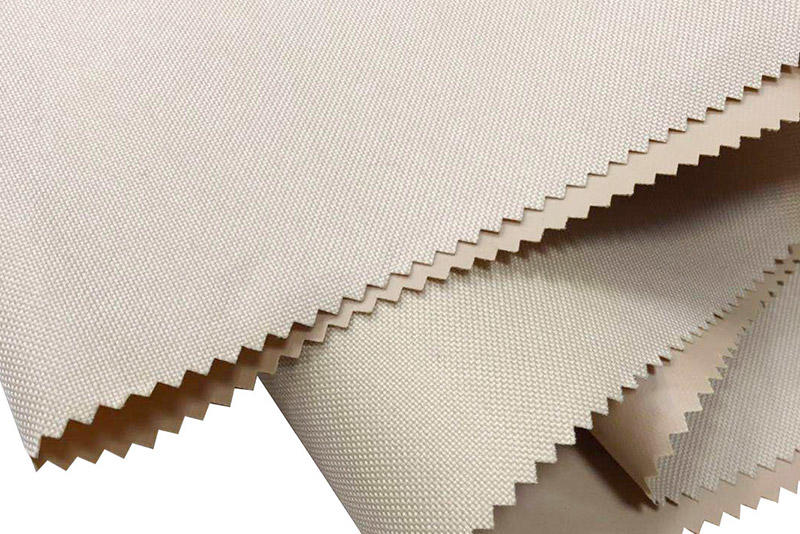

However, it is precisely because of the light weight of nylon fabrics that nylon fabrics are generally softer, easily deformed under the action of external force, and have no sense of support. If the nylon fabrics are not treated with relevant coatings, the backpacks produced are also soft. There is no rigid three-dimensional sense. The more three-dimensional and stylish nylon business backpacks seen on the market are basically treated with pvc or PU coated rubber particles, so the backpack version made is more three-dimensional and beautiful. higher degree.

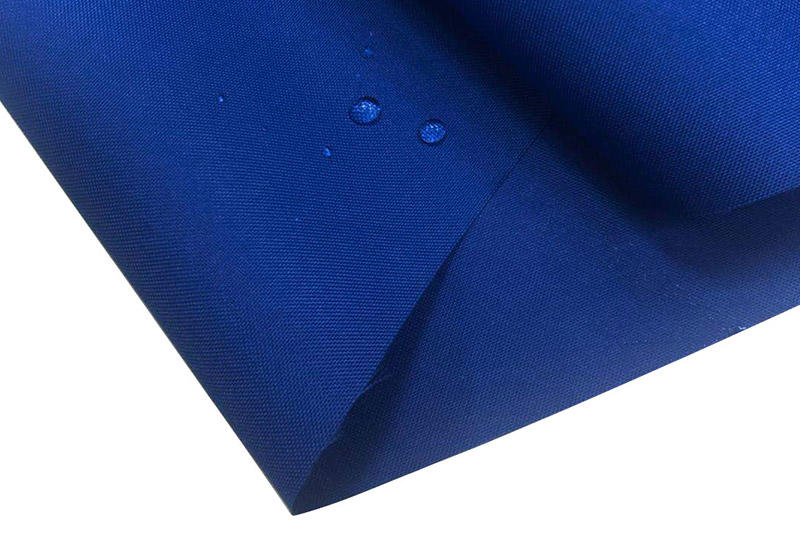

There are many processing techniques for nylon fabrics. Different processing techniques can make nylon fabrics have different functions. For example, nylon fabrics can be treated with waterproof coating to obtain waterproof nylon fabrics. In addition, there are nylon fabrics with different functions such as anti-fouling, oil-proof, anti-static, etc., which can meet the different requirements of different custom parties for fabrics.

Nylon fabrics are expressed in units of fineness (fineness of fibers, that is, fineness). Mass in grams at moisture regain. For example, when the weight of 9000 meters long nylon fiber is 600 grams, the fineness is represented by 600D, which can also be called 600D nylon. At present, the commonly used nylon fabrics on the market are 70D, 210D, 300D, 420D, 600D, 840D, 900D, 1000D, 1680D, etc. When the density of the fiber is constant, the larger the denier, the thicker the fiber, the more obvious the fabric texture, and vice versa. , the smaller the denier, the finer the fiber and the less obvious the fabric texture.

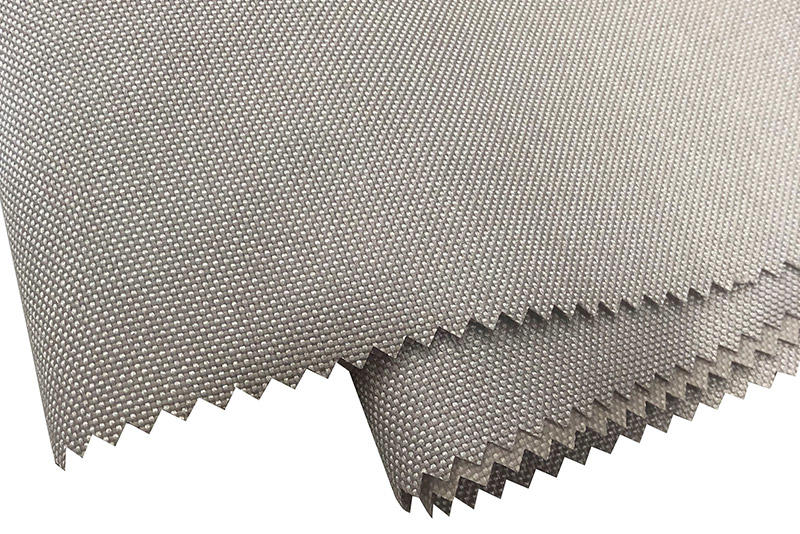

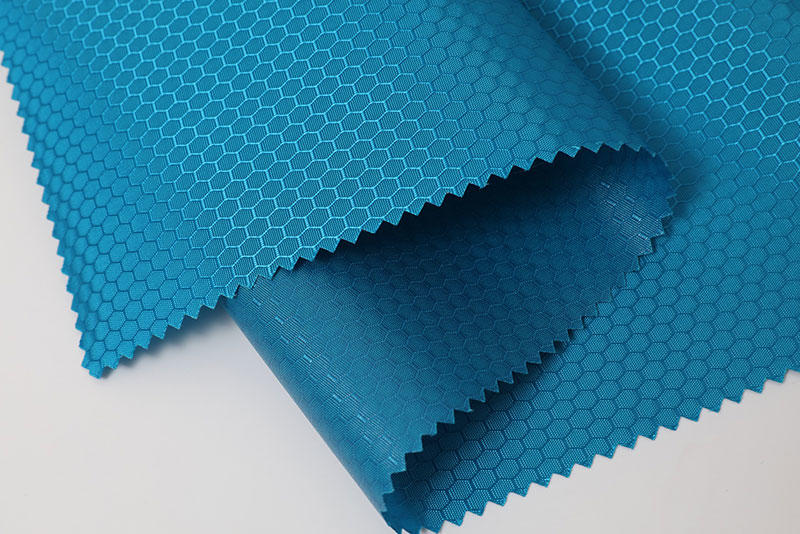

In the weaving process of nylon fabrics, different fabric patterns are formed on the fabric due to different yarn fineness and different warp and weft structures. According to different fabric patterns, nylon fabrics can be divided into twill nylon, ballistic nylon, and pullable nylon. , Honeycomb nylon and so on.

Business backpacks are custom-made. The effect of nylon fabrics with different deniers and patterns is different. If the customizing party does not know the fabric material and does not know which denier nylon fabric to choose, you can first determine your own budget. , and then find a professional backpack manufacturer, let the manufacturer recommend suitable fabrics for customization according to your needs.

English

English 简体中文

简体中文 русский

русский Español

Español