With the increasing global environmental awareness and the popularization of the concept of sustainable development, recycled polyester fabric is rapidly becoming an important trend in the textile industry. This environmentally friendly material made from recycled plastic bottles, waste textiles and other waste not only reduces resource waste and environmental pollution, but also injects new vitality into the fashion industry.

The biggest advantage of recycled polyester fabric is its environmental friendliness. According to statistics, every ton of recycled polyester fabric produced can reduce about 3 tons of carbon dioxide emissions and save about 60,000 liters of water resources. In addition, it can effectively reduce the harm of plastic waste to the environment and contribute to the development of the circular economy.

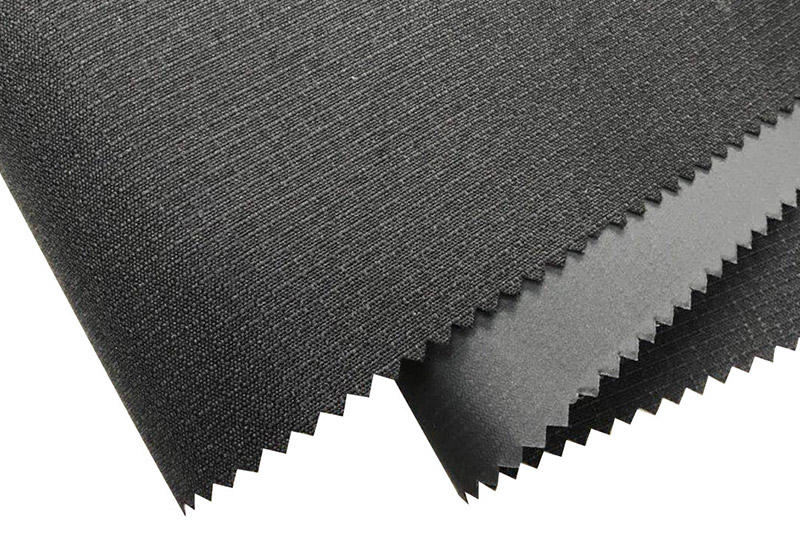

High Performance

Recycled polyester fabric inherits the advantages of traditional polyester fabrics, such as high strength, abrasion resistance and wrinkle resistance. These characteristics make it very suitable for making products that require durability, such as outdoor clothing, sportswear and luggage.

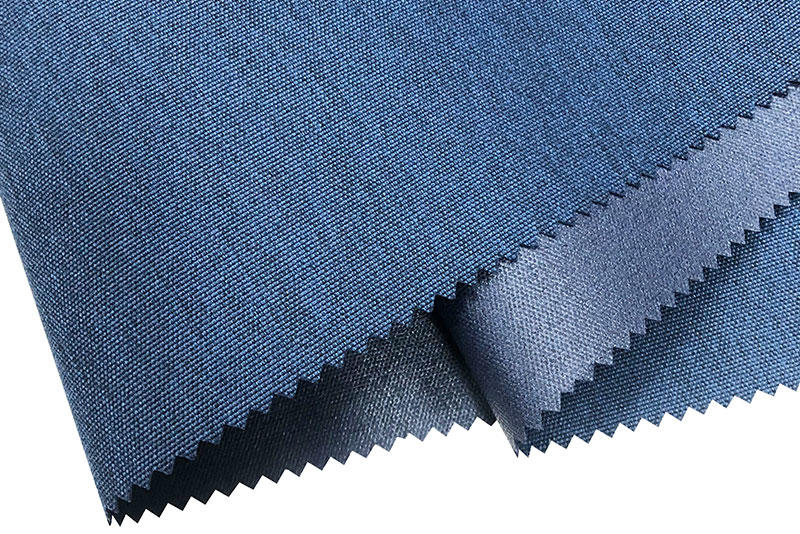

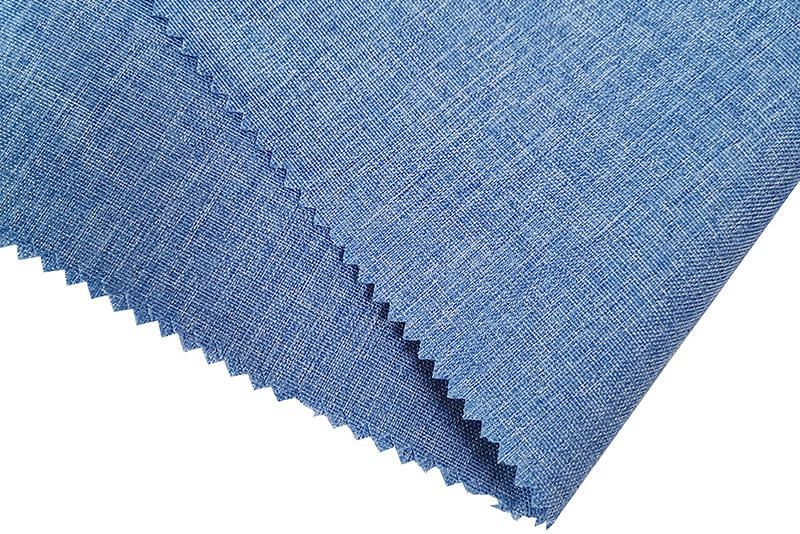

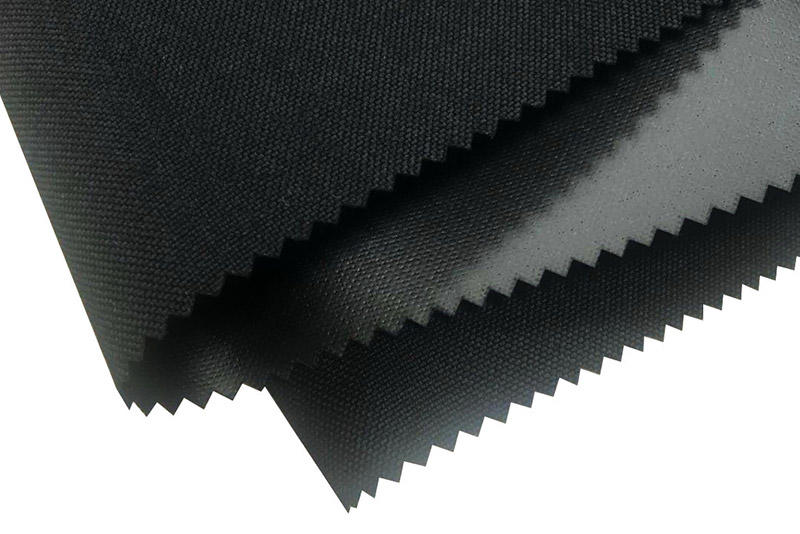

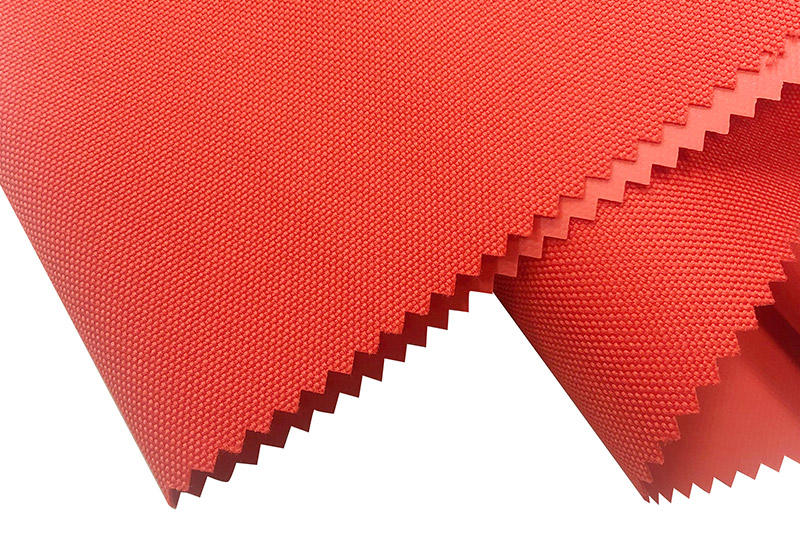

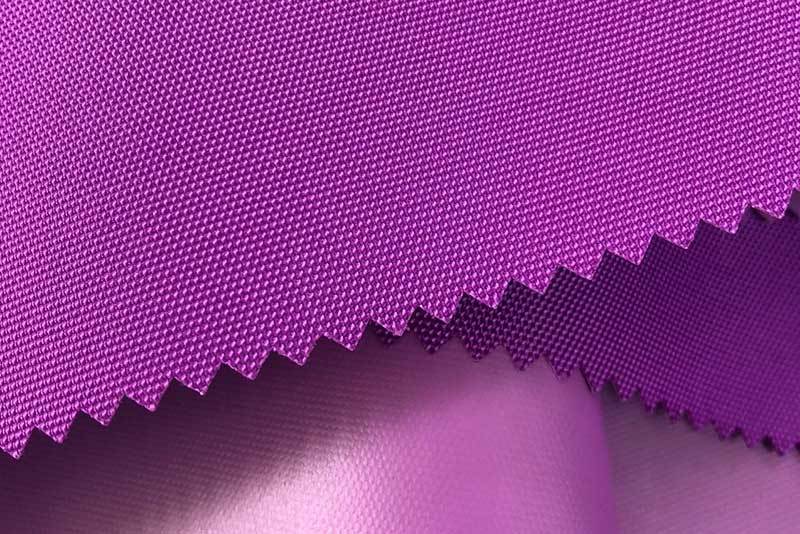

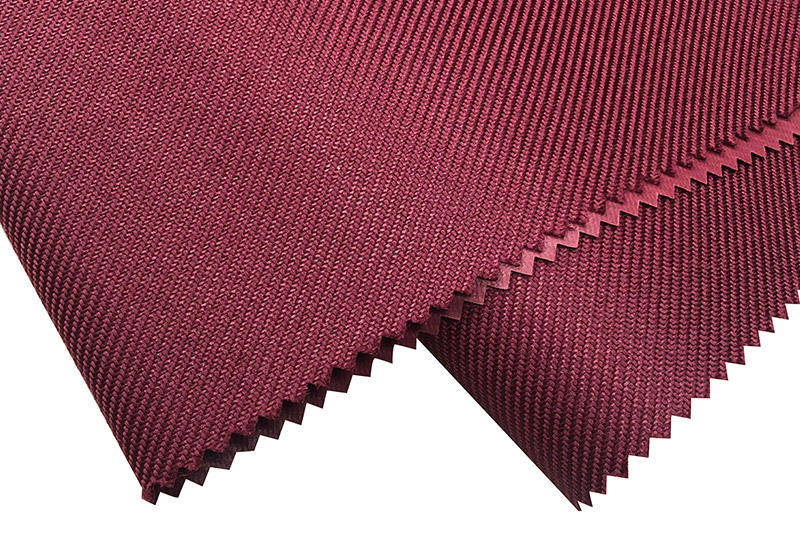

Diversity

Recycled polyester fabric can present a variety of textures and appearance effects through different textile processes and finishing technologies, from soft and comfortable knitted fabrics to crisp and durable woven fabrics. This allows it to meet the needs of different application scenarios.

Economical

With the advancement of technology and the promotion of large-scale production, the cost of recycled polyester fabrics is gradually decreasing. Compared with traditional polyester fabrics, its price gap is getting smaller and smaller, and it has higher social value and brand premium ability.

Traceability

Many manufacturers of recycled polyester fabrics provide transparent supply chain information. Consumers can understand the source and production process of the product through the certification label, thereby enhancing their trust in the brand.

Production process of recycled polyester fabrics

The production of recycled polyester fabrics usually includes the following key steps:

Raw material collection and sorting

After the discarded plastic bottles, industrial waste or old clothes are collected, they are washed, crushed and sorted to remove impurities and ensure the purity of the raw materials.

Melting and granulation

The treated plastic fragments are heated and melted to form polyester granules. These granules are the basic raw materials for recycled polyester fibers.

Spinning and weaving

Polyester granules are made into fibers through the spinning process, and then they are processed into fabrics through textile processing. This process is similar to the production of traditional polyester fabrics, but with lower energy consumption and less pollution.

Finishing

Dyeing, printing or other functional treatments are performed on the fabrics as needed to enhance their appearance and performance.

Application areas of recycled polyester fabrics

Apparel industry

Recycled polyester fabrics are widely used in the production of sportswear, casual wear and outdoor clothing. Its light, breathable and easy-to-clean characteristics are deeply loved by consumers, and it also meets the pursuit of environmental protection and sustainable development by modern consumers.

Home decoration

Recycled polyester fabrics are also increasingly used in home textiles such as bed sheets, curtains, and sofa covers. Its durability and easy maintenance make it an ideal choice for home decoration.

Industrial textiles

In the industrial field, recycled polyester fabrics are used to make filter materials, protective clothing, automotive interiors, and architectural membrane structures. Its high strength and weather resistance enable it to adapt to a variety of demanding application scenarios.

Fashion accessories

Fashion accessories including handbags, hats, scarves, etc. also often use recycled polyester fabrics. Its unique texture and diverse color options provide designers with rich creative space.

Future development trend of recycled polyester fabrics

As consumers pay more attention to environmental protection and sustainable development, the market prospects of recycled polyester fabrics are very broad. The following are some trends that may dominate future development:

Technological innovation

Develop more efficient recycling technologies and production processes to further improve the quality and performance of recycled polyester fabrics while reducing costs.

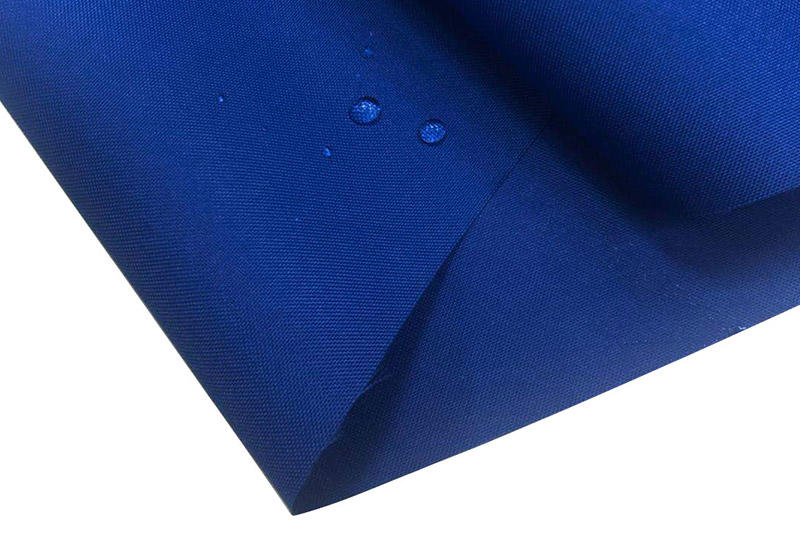

Multifunctional integration

Through composite technology, antibacterial, flame retardant, waterproof and other functions are integrated into recycled polyester fabrics to meet diverse needs.

Brand cooperation

More and more internationally renowned brands have begun to adopt recycled polyester fabrics and launch environmentally friendly series of products to attract consumers who focus on sustainable development.

Policy support

Governments are introducing more policies to support the circular economy, encourage companies to use recycled materials, and promote the popularization of recycled polyester fabrics.

Recycled polyester fabrics are redefining the future of the textile industry with their excellent environmental performance and diverse application potential. Whether it is to enhance the aesthetics or functionality of the product, it has demonstrated great market value. In the future, with the continuous advancement of technology and the enhancement of consumers' environmental awareness, recycled polyester fabrics will surely shine in more fields and create higher economic and environmental benefits for human society.

English

English 简体中文

简体中文 русский

русский Español

Español