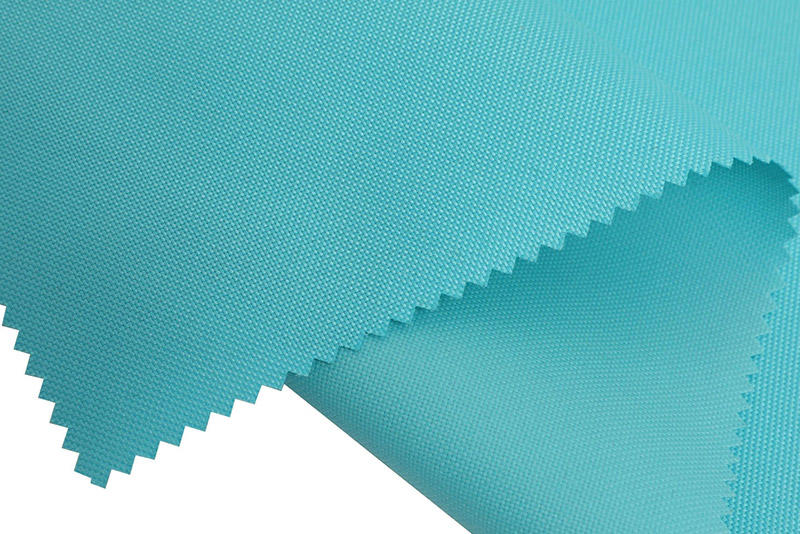

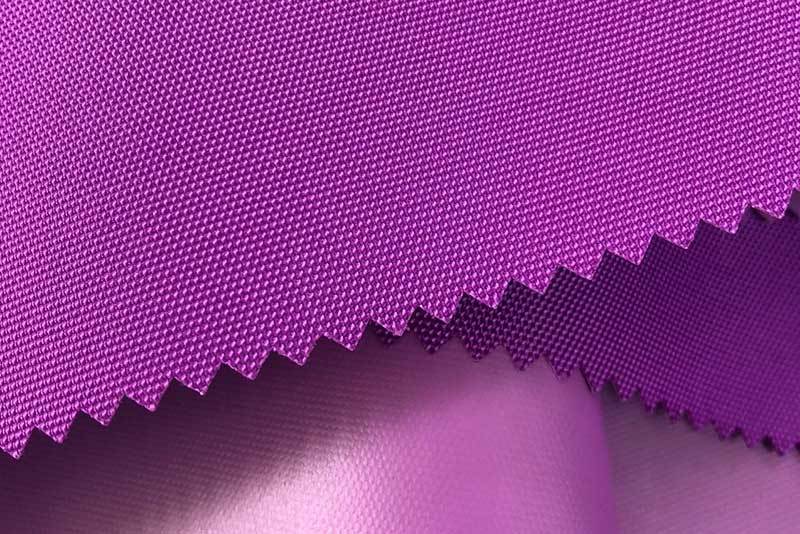

Ripstop fabric is renowned for its exceptional durability and tear resistance, making it a go-to material for a variety of applications, from outdoor gear and military uniforms to industrial and aerospace textiles. At the heart of its robust design lies the ingenious ripstop weave pattern, a grid-like structure strategically engineered to prevent tears from spreading. This weave integrates thicker, stronger threads into a finer base fabric, creating a reinforced grid that acts as a barrier against further damage when a tear begins.

When stress or sharp objects compromise a section of the fabric, the thicker threads in the grid immediately absorb and redistribute the force, effectively isolating the damage to the small area between the gridlines. This containment prevents a minor rip from turning into catastrophic fabric failure, a feature that is critical in high-stakes environments like mountaineering, military operations, or extreme sports. The grid pattern's impact on performance is not merely functional; it also adds a unique aesthetic touch, with the visible square weave often becoming a signature look for outdoor and technical products.

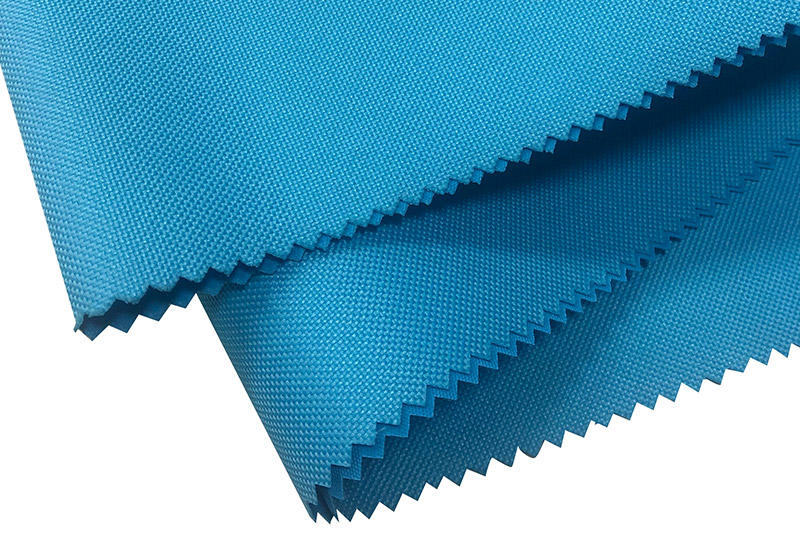

The size of the grid plays a pivotal role in determining the fabric’s effectiveness and suitability for various uses. Smaller grid sizes typically offer higher resistance to spreading tears since the intervals between reinforced threads are shorter, leaving less room for rips to expand. This makes finer grids ideal for lightweight and compact items such as kites, ultralight tents, or parachutes, where both durability and minimal weight are crucial. On the other hand, larger grids allow for thicker reinforcement threads, enhancing the material's strength for heavy-duty applications such as industrial tarps or military gear, where rugged performance outweighs the need for lightness. Choosing the right grid size is therefore a careful balance between weight, flexibility, and the level of protection required for the intended use.

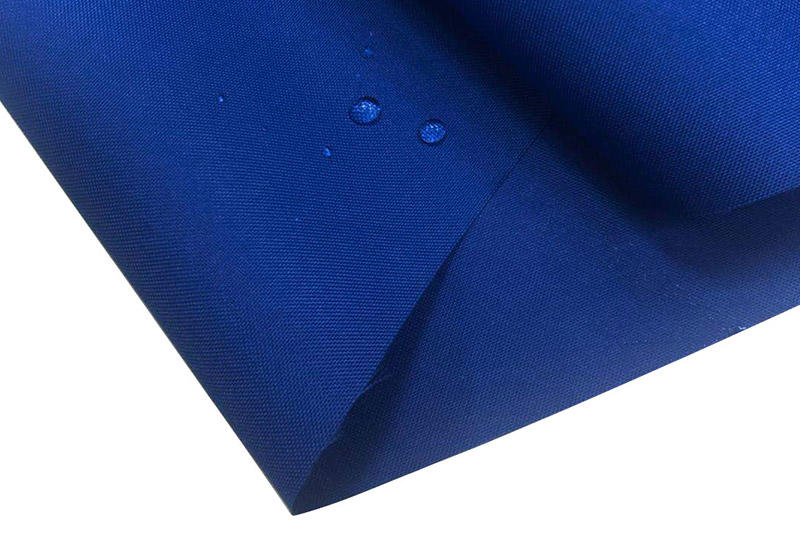

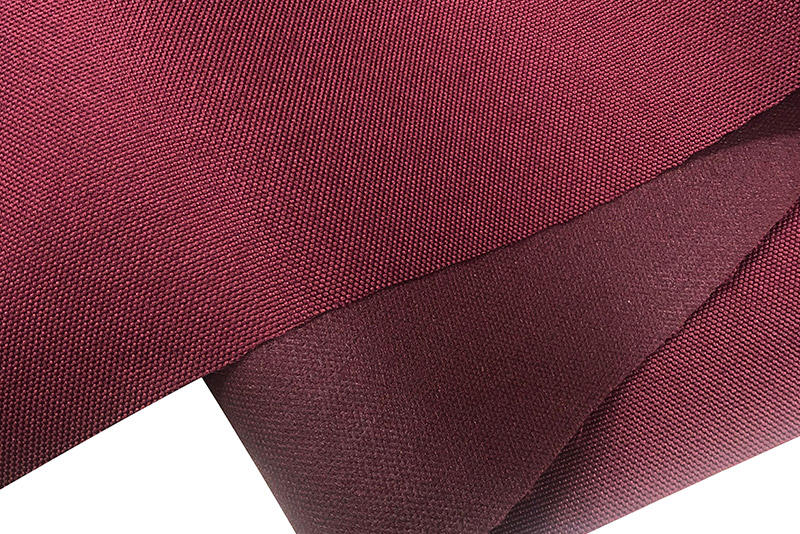

Beyond the weave, the material composition of ripstop fabric also influences its performance. Common materials like nylon and polyester are chosen for their inherent tensile strength, while blends with cotton or other natural fibers can offer enhanced comfort and breathability. Modern innovations have further enhanced ripstop’s properties, with treatments such as waterproof coatings, UV resistance, and even flame retardancy expanding its versatility. The ability to customize ripstop fabric, from its composition and coatings to its grid size, makes it a highly adaptable material for a broad spectrum of industries.

Ripstop’s durability also extends to its maintenance. Its tear-resistant nature ensures longevity even under heavy use, but proper care—such as avoiding excessive heat during washing and minimizing prolonged exposure to direct sunlight—can further extend its lifespan. Additionally, sustainability efforts in textile production have introduced eco-friendly and recycled ripstop options, which maintain high performance while reducing environmental impact. These developments highlight the fabric’s relevance not only in performance but also in aligning with modern values of sustainability.

In essence, the ripstop weave pattern exemplifies how innovative design can amplify a material’s utility and resilience. By interweaving robust threads into a grid, it ensures that strength and practicality are woven into every square inch, protecting against the unpredictabilities of real-world challenges. Whether scaling mountains, braving harsh climates, or enduring the wear and tear of daily life, ripstop fabric stands as a testament to how thoughtful engineering can enhance both functionality and reliability.

English

English 简体中文

简体中文 русский

русский Español

Español