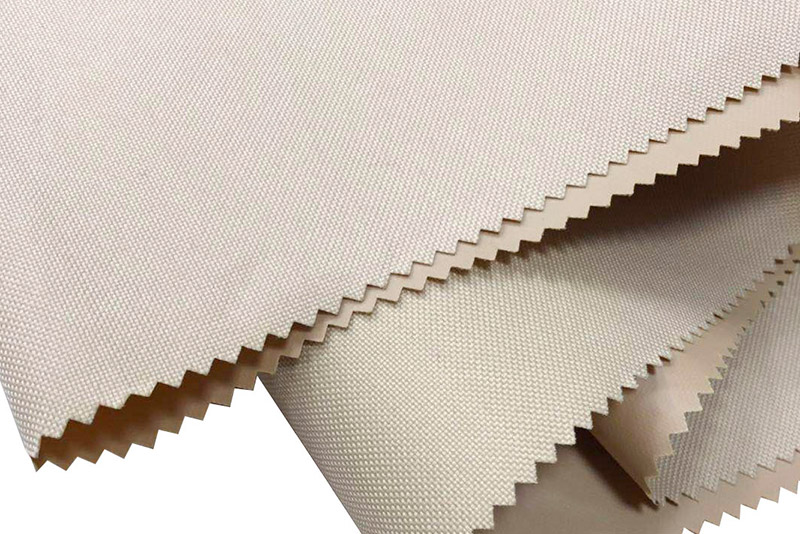

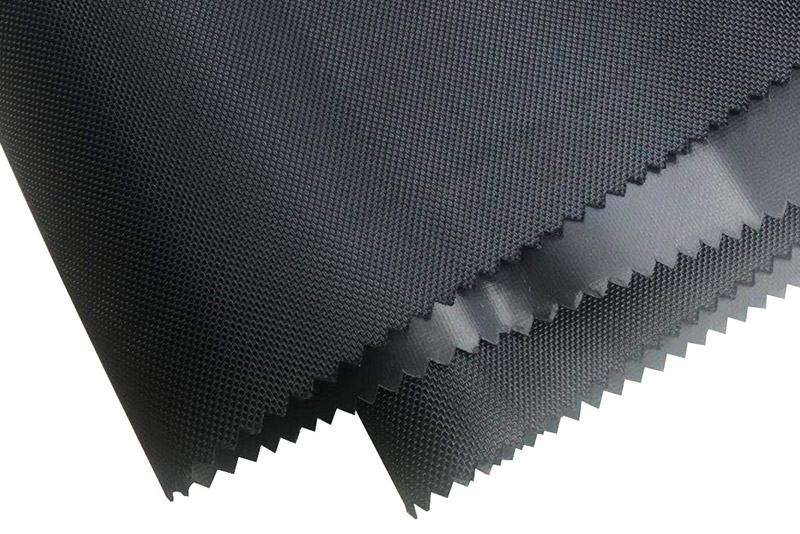

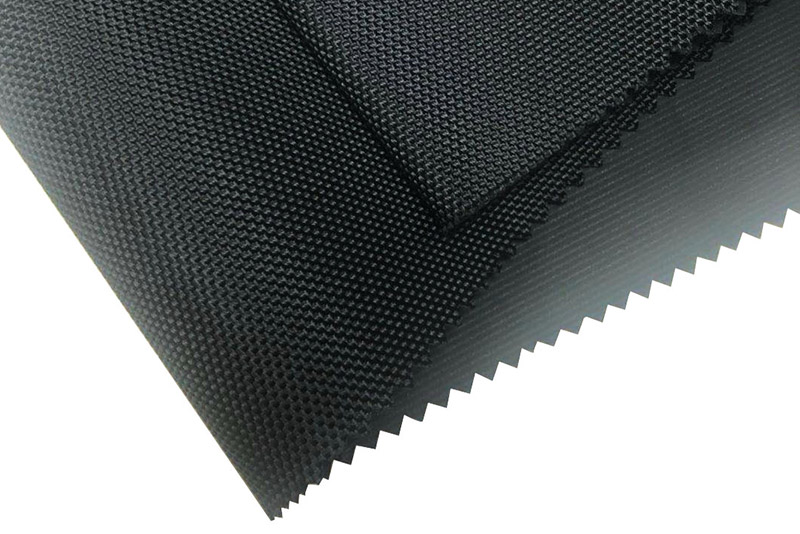

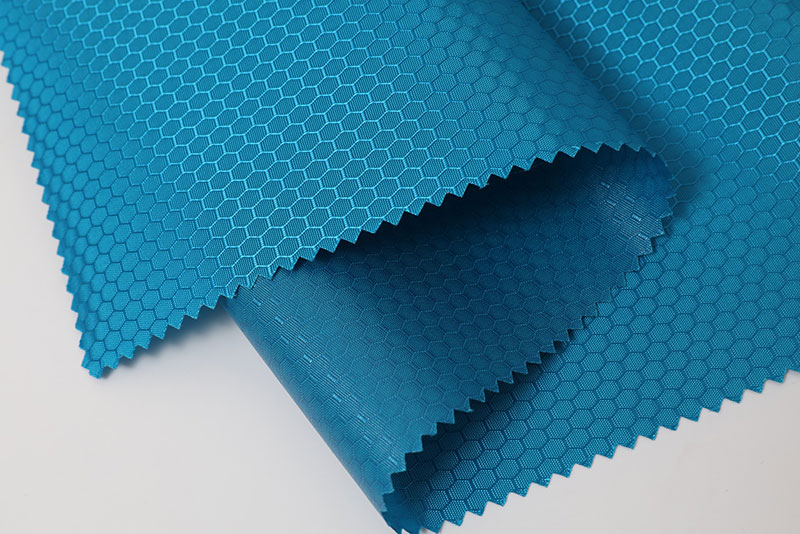

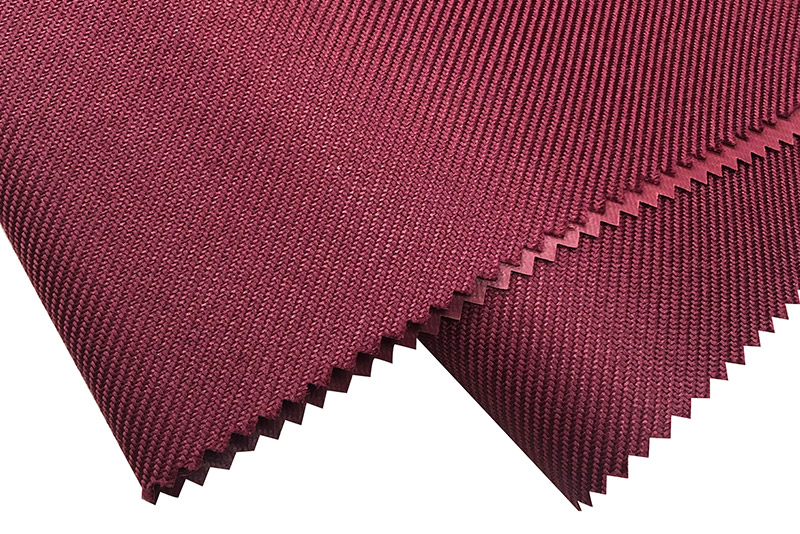

Ripstop fabric is a durable, woven material that features a distinctive grid-like pattern, typically made with thicker threads that are interwoven at regular intervals. The pattern itself helps prevent the fabric from tearing further if it sustains damage, making it significantly more durable than standard fabrics. Ripstop fabrics can be made from a variety of materials such as nylon, polyester, or cotton, but nylon and polyester are the most common due to their lightweight and resilient nature.

The grid pattern is usually visible as squares or diamonds that provide reinforcement to the material. This reinforcement is what gives ripstop fabric its strength and resistance to tears. When a rip or puncture occurs, the pattern acts as a barrier, preventing the tear from spreading across the fabric.

Ripstop fabric’s strength comes from its unique weaving process. In a typical woven fabric, the threads are arranged in a simple crisscross pattern, but in ripstop fabric, thicker threads are woven into the fabric at regular intervals, creating a grid-like structure. This reinforcement increases the fabric’s tensile strength, making it much less likely to tear or stretch.

The reinforced threads are often made of nylon or polyester, which are both known for their resistance to moisture and UV damage. In addition to providing structural integrity, these materials make ripstop fabric resistant to the elements, adding another layer of functionality to its design. The woven grid ensures that even if the fabric is punctured or torn, the damage is localized and does not spread throughout the material, which is crucial in many applications.

Ripstop fabric’s ability to resist tearing and its lightweight nature make it suitable for a wide range of applications. Below are some of the most common uses of ripstop fabric:

Ripstop fabric is a staple in the production of outdoor gear. Whether it’s tents, backpacks, sleeping bags, or jackets, ripstop fabric is chosen for its durability, tear resistance, and lightweight properties. Outdoor enthusiasts appreciate its ability to withstand the rigors of nature, such as rough terrain, sharp objects, and harsh weather conditions. For example, tents made from ripstop fabric are less likely to tear when exposed to windy conditions or rough ground.

One of the original uses of ripstop fabric was in military applications. The fabric’s resistance to tears and abrasions makes it an excellent choice for military uniforms, parachutes, and other tactical gear. Soldiers and personnel in hazardous conditions rely on ripstop fabric to withstand the physical demands of their work while remaining lightweight and comfortable. Ripstop fabric’s use in parachutes, in particular, is vital for ensuring safety by preventing catastrophic rips or failures during descent.

Ripstop fabric is commonly used in sports equipment, including kites, sails, and inflatable boats. The fabric’s lightweight yet durable qualities help reduce the overall weight of the equipment, while the tear-resistant properties ensure that the items perform well under stress. Whether it’s a sailboat on the ocean or a kite soaring through the sky, ripstop fabric holds up to intense forces without compromising performance.

In industries where workers are exposed to physical stress or harsh environments, ripstop fabric is often used to make protective clothing, such as coveralls, safety vests, aprons, and gloves. The fabric’s ability to resist tearing, even when subjected to abrasions, makes it an ideal material for protective workwear. This type of clothing is essential for industries such as construction, manufacturing, and emergency services, where durability is crucial for worker safety.

Ripstop fabric is also used in the production of bags, luggage, and backpacks, where strength and lightweight performance are key considerations. Backpacks made with ripstop fabric are not only durable enough to withstand heavy loads and rough handling, but they are also resistant to tears, making them ideal for outdoor adventures and travel. Additionally, the material’s flexibility ensures that the bags remain comfortable to carry, even when fully packed.

English

English 简体中文

简体中文 русский

русский Español

Español