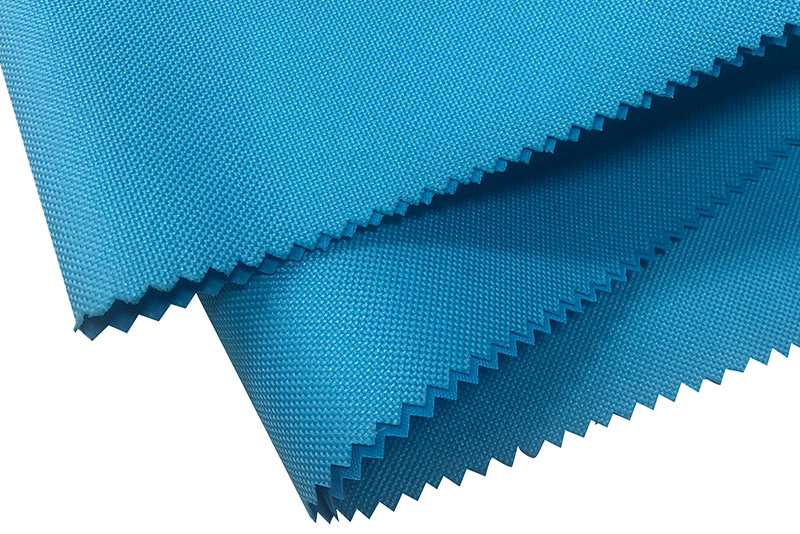

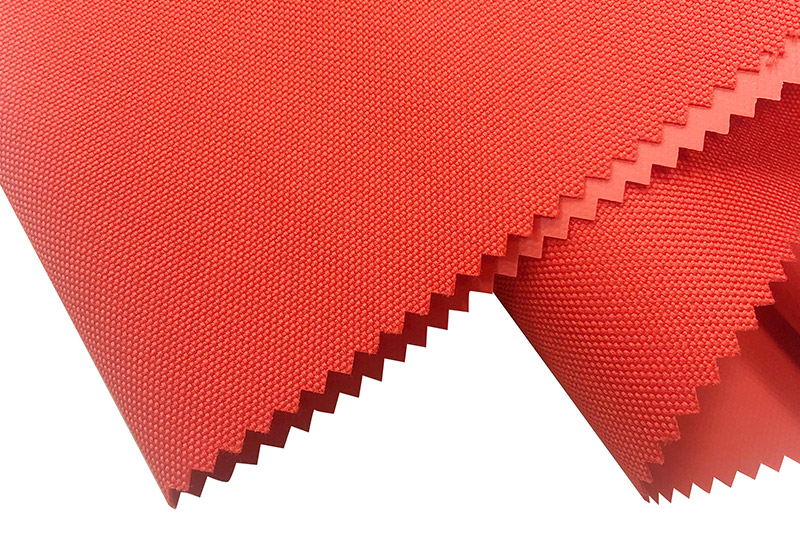

In the process of customizing backpacks, the selection of fabrics is one of the highlights. When selecting fabrics, professional backpack manufacturers will carefully compare the parameters of the fabrics, such as the denier, gram weight, door width and other parameters of the fabrics, and then evaluate the performance of the fabrics , whether the finished product effect meets the requirements of customized customers, so as to select and determine the fabric in the future. The size of the fabric parameters can directly reflect the density, texture thickness, firmness and durability of the fabric. Today, Hangzhou Gaoshi Luggage Textile Co.,Ltd. will take you to understand the specific weight of fabrics.

"Gram weight" is a unit of measurement for textiles, which means that under a standard unit of measurement, the unit of weight in grams is the measurement standard. The grammage of the fabric is the weight of the fabric per square meter, and the unit is "grams per square meter" (g/m2), abbreviated as FAW. For example, the gram weight of 1 square meter of nylon cloth is 300 grams, which is expressed as: 300g/m², etc., which is a unit of weight. The higher the weight of the fabric, the better the quality and the more expensive the price. On the contrary, the lower the weight of the fabric, the lower the price and the lower the quality.

The choice of the gram weight of the fabric for making the backpack is directly related to the quality of the backpack and the customized price. Even the same kind of fabric will have different gram weights due to different yarn counts. When customizing the backpack, you can explain your own customization to the manufacturer. demand, so that manufacturers can find the fabric material corresponding to the gram weight.

English

English 简体中文

简体中文 русский

русский Español

Español