1. The production process of polyester mainly includes two parts: polyester melt synthesis and melt spinning.

2. The raw materials for synthesizing polyester are polyethylene terephthalic acid and ethylene glycol, which are mainly obtained from petroleum cracking, and can also be obtained from coal and natural gas. After the polyester melt is produced, it can be melt spun to finally form polyester fabric.

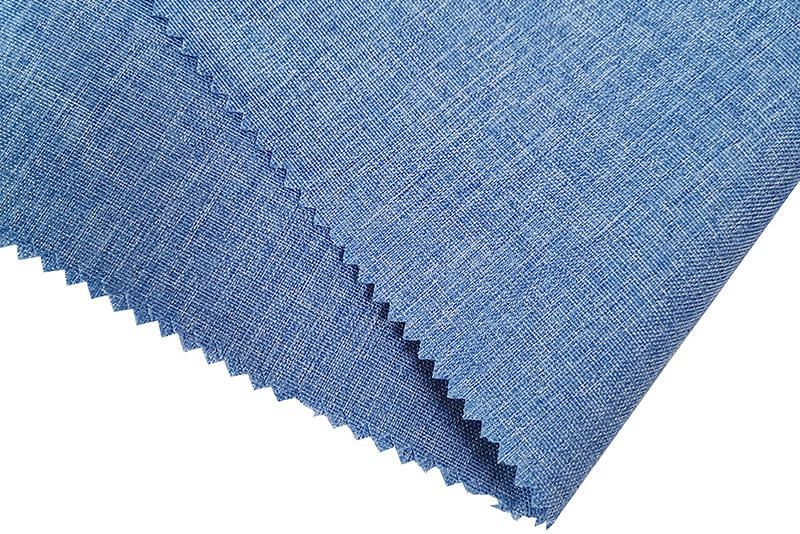

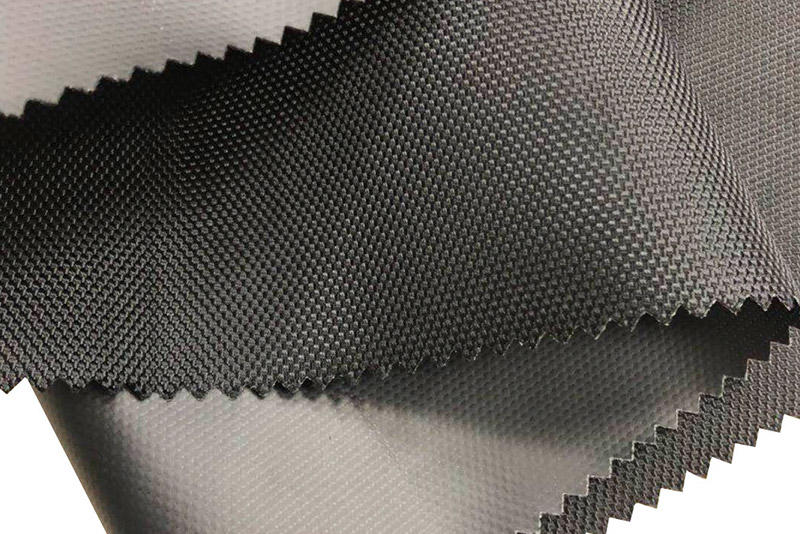

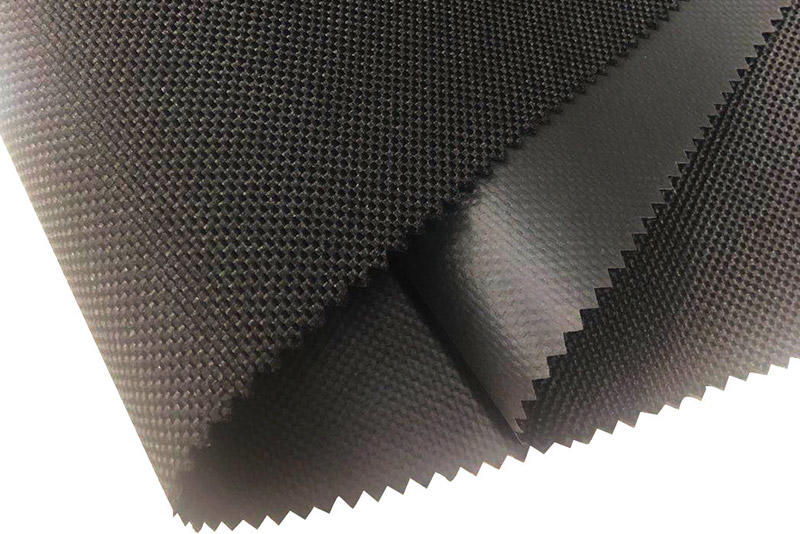

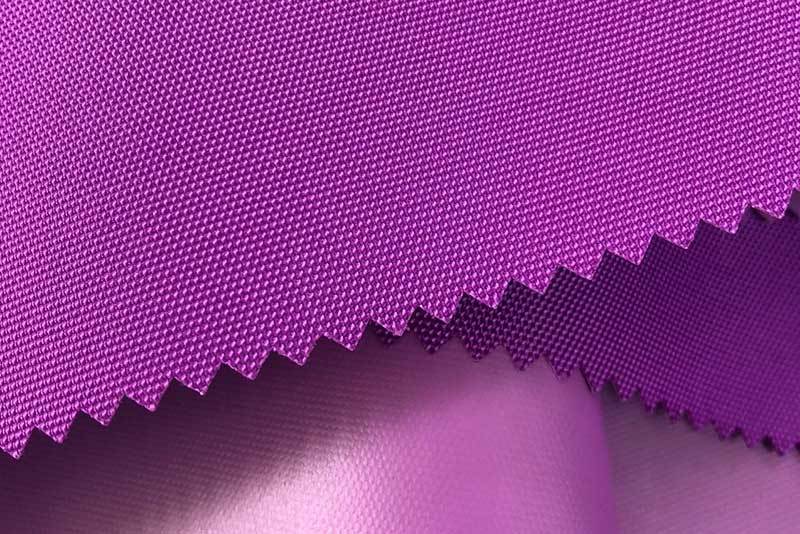

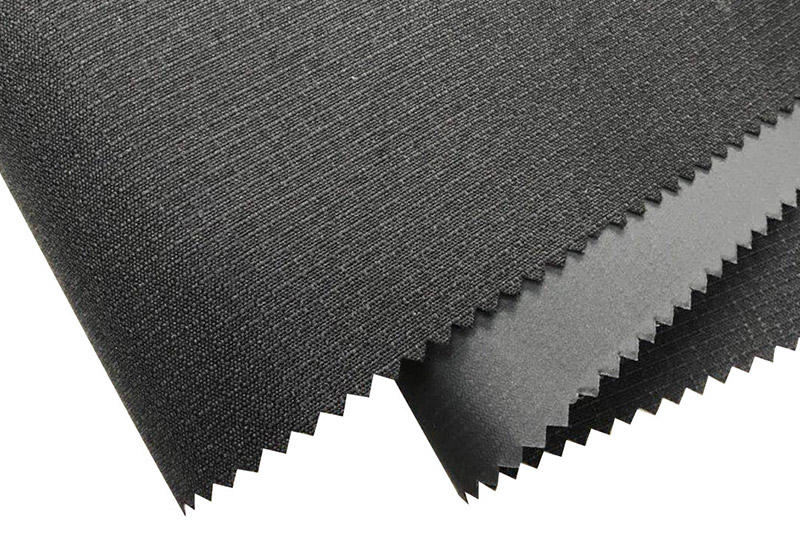

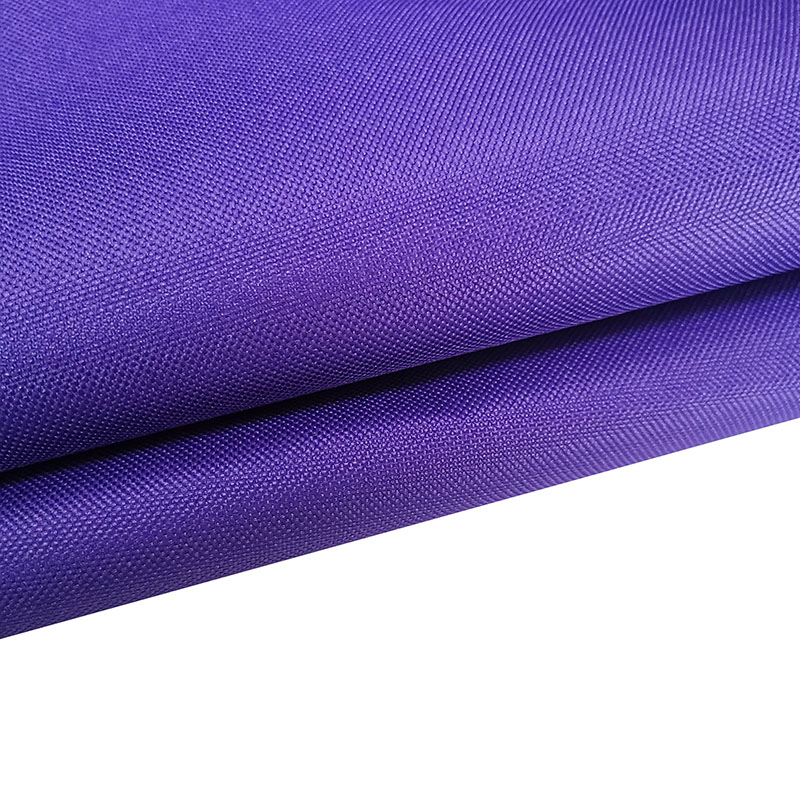

3. Polyester has a smooth surface and has the advantages of high strength, no deformation, no distortion, and durable pleats, so it is especially suitable for use as clothing fabrics. And polyester also has very good acid resistance, alkali resistance, abrasion resistance and resilience.

4. However, compared with natural fibers, polyester has the disadvantages of low moisture content, poor air permeability, poor dyeability, easy pilling, and easy contamination.

English

English 简体中文

简体中文 русский

русский Español

Español