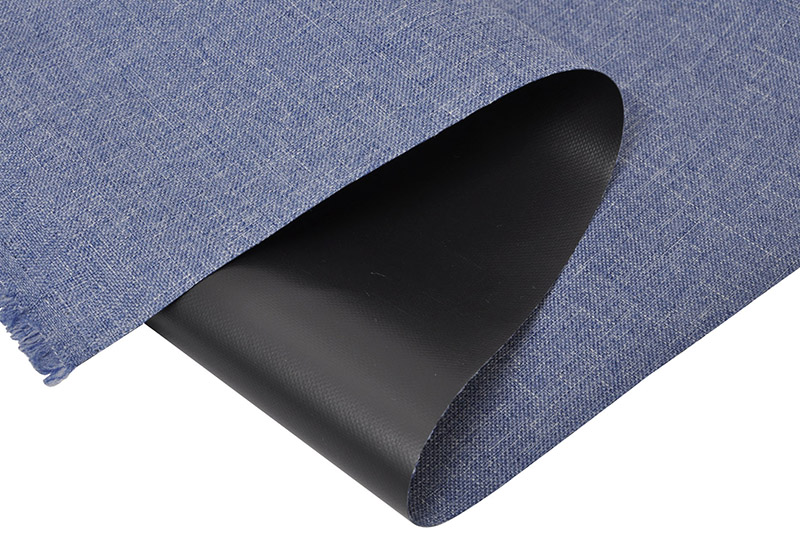

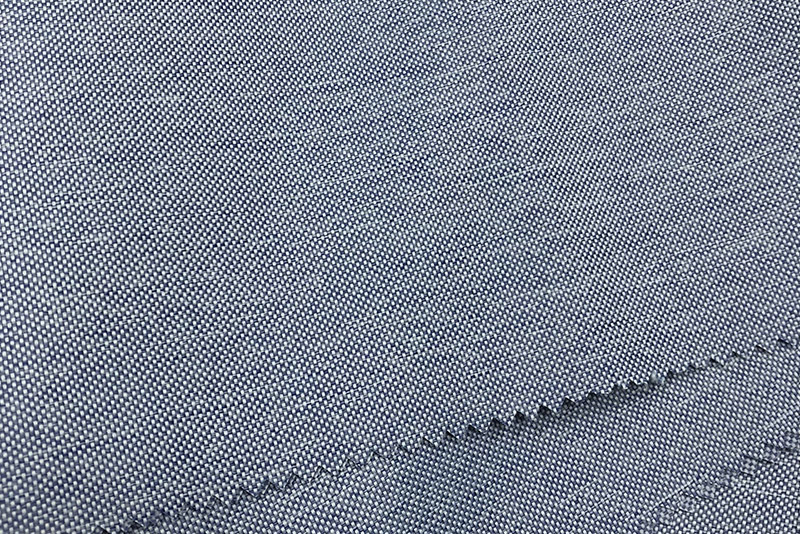

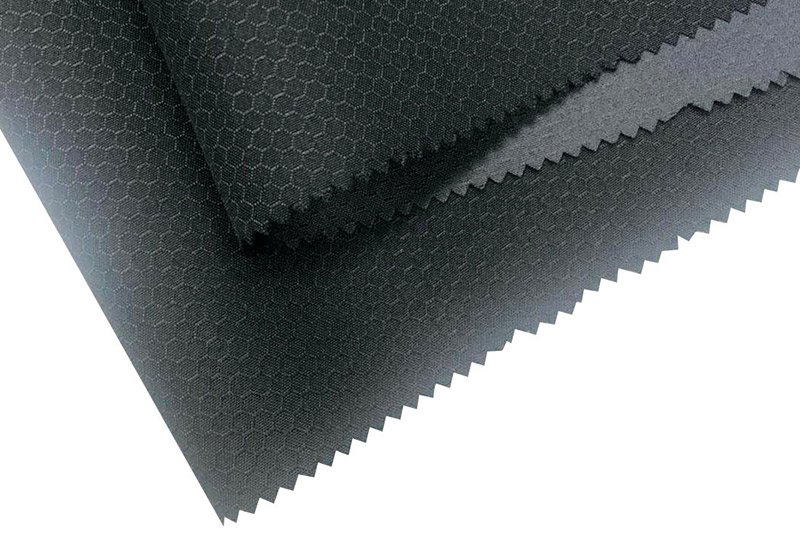

It is mostly used for the outer and inner materials of bags. Surface: The fabric should not have drawnwork, the stripes of the yarn should be clear and the color should be uniform, the number of horizontal and straight lines of the yarn should be enough, the thickness of the yarn should be enough, and the yarn should be (tested by a measuring instrument); rubber bottom: the glue is firm and will not degummed. , The rubber bottom will not rise (it won't whiten after being grasped by hand, keep the original rubber background color); force: merge the car in the horizontal and straight direction so that it will not crack after pulling it hard. Colored materials should also pay attention to whether there are reinforced colors, especially for bright colors, it is more likely to produce dyeing phenomenon, the color matching is not good enough that the finished product finds everything is too late!

It is mostly used between the fabric and the lining of the bag, and the finished bag cannot be seen. It mainly depends on whether the thick bottom and density are enough (whether one square has enough weight). Good cotton is elastic and not easy to pull apart.

It must be elastic, strong, not easy to break, and no yarn breakage.

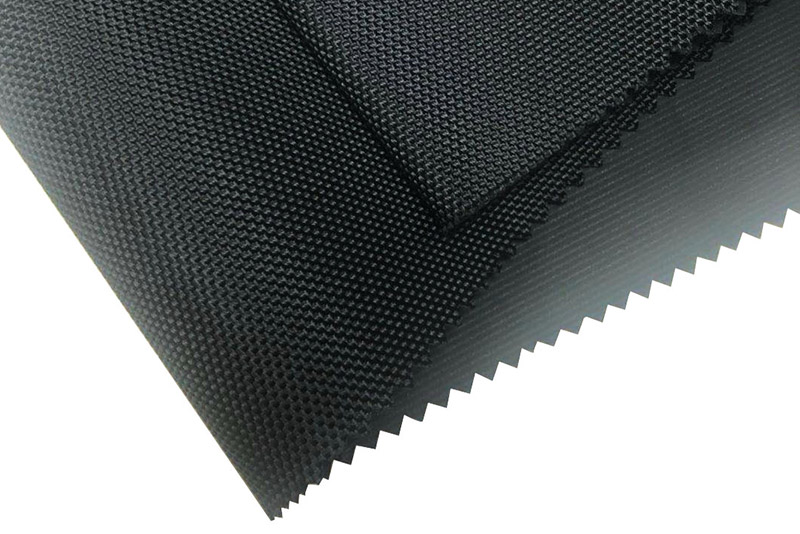

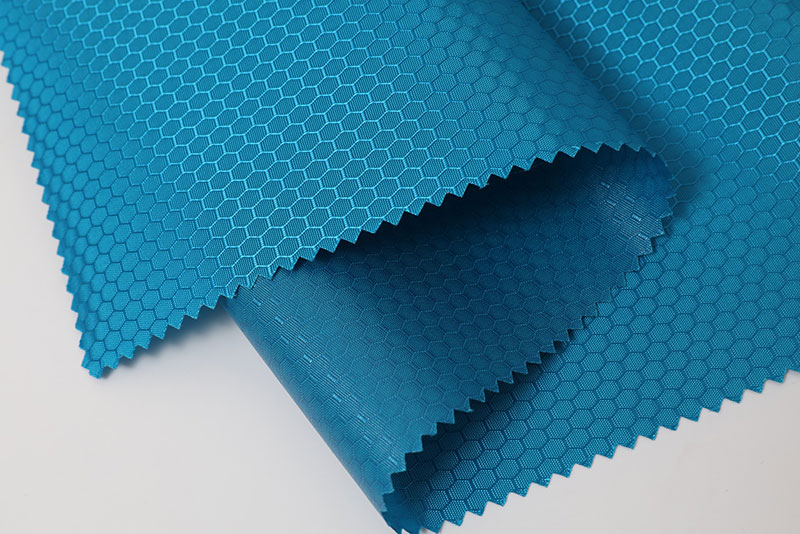

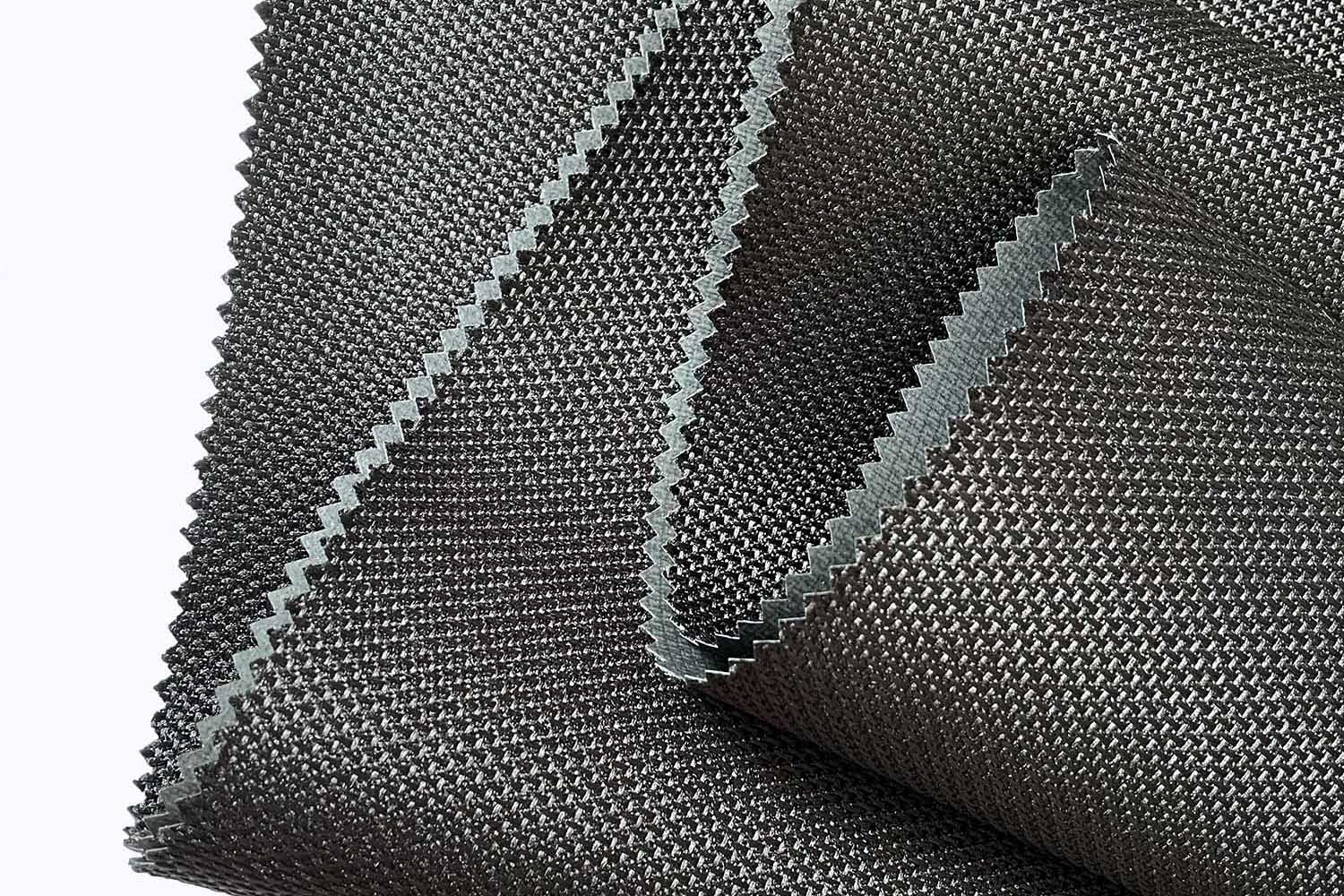

There are many types of webbing, such as plain weave, fine grain, pit pattern, etc., but each different specification of webbing has a standard weight. From the outside, look at whether the edges are smooth, the surface is uniform, lint-free, no yarn drawn, no dyeing, etc.

English

English 简体中文

简体中文 русский

русский Español

Español